For over 50 years

Quality made in Austria

70 years of company history, 50 years of brand success

Since its inception, Austropressen has consistently focused on designing and manufacturing effective solutions for recycling & waste management. The high quality of our compactors and balers combined with our experience guarantee that countless companies from all over the world are satisfied Austropressen customers. For more than 50 years, in 100 countries and across all sectors.

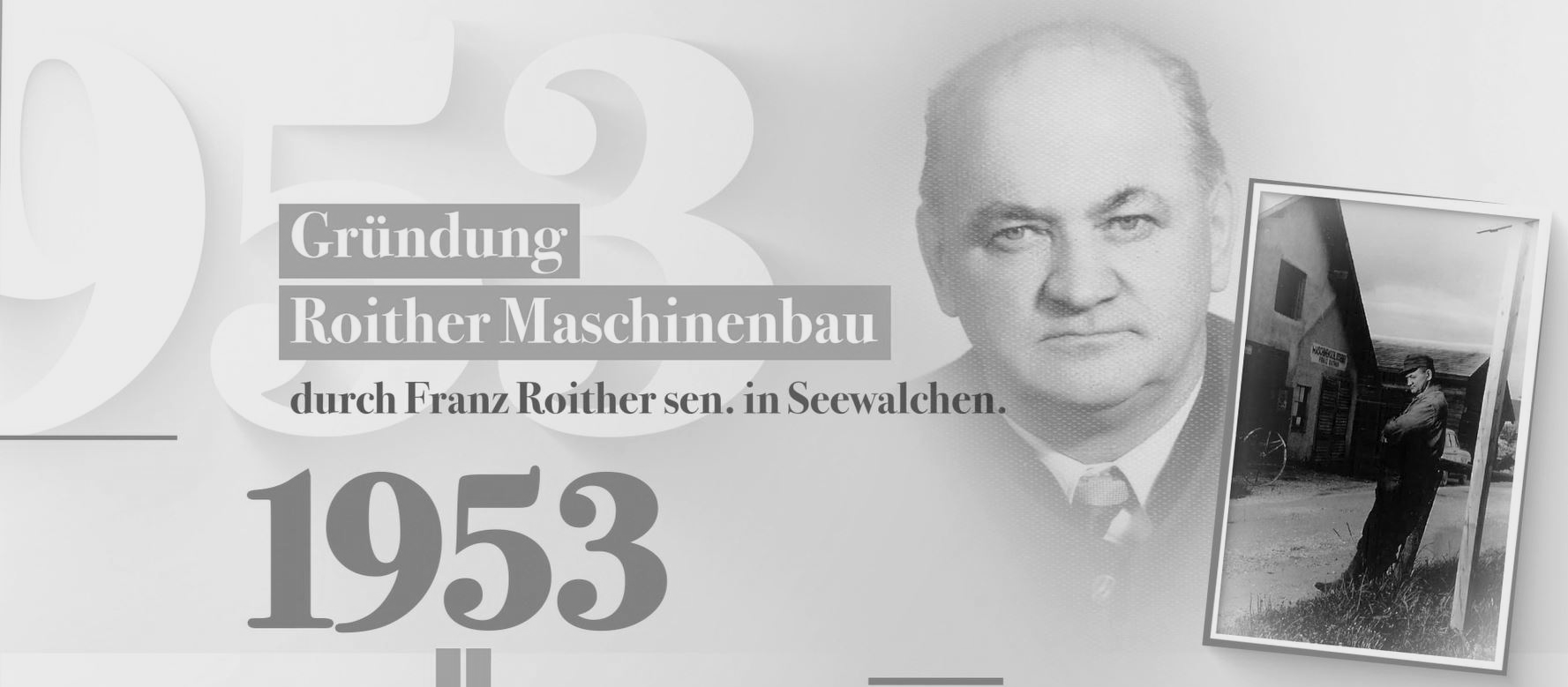

Company foundation 1953Locksmith's shop with forging work

Locksmith's shop with forging work

In 1953, Franz Roither Senior opened a small locksmith's shop in Seewalchen am Attersee. In addition to the locksmith and blacksmith work required in a village, Roither also carried out work that took a special idea or a solution. He manufactured smaller machines for agriculture and industry and carried out repairs. Roither Senior also built the first presses, including veneer, mechanic and fruit presses.

Brand foundation 1973Austropressen is founded

Austropressen is founded

In 1973, son Franz Roither Junior togther with his wife Mathilde Roither founds the Austropressen brand, specialising in mechanical engineering and environmental technology. The first product to be launched on the market is a vertical baler. This has been a true success story for over 50 years. From the very beginning, the company has been characterised by a pioneering spirit, innovative strength and individuality. Initially, special machines and customised solutions were manufactured for neighbouring companies and the first developments were patented. At the same time, the demands in terms of product requirements increased. The pleasing consequence: continuous developments in waste and baling presses, customised solutions for a wide range of recyclable materials and the first deliveries beyond Austria's borders.

Third generation 2023Sibling trio takes the lead

Sibling trio takes the lead

Today, Austropressen still develops and produces 100% of its entire product range at its headquarters in Seewalchen am Attersee, Austria. It supplies customised waste disposal solutions to around 100 countries worldwide. Expertise, innovative strength and smooth service come exclusively from the family business with around 50 competent and experienced employees.

The sibling trio Marlene (marketing), Philipp (management & production) and Lukas Roither (sales) are responsible for the future of the company. The focus remains clearly defined: a brand company with continuous product development and strong apprentice and specialist training programmes.

- 50+

Employees

- 100+

Countries

- 100 %

Family-run business

Reliability

Durability & innovation. Small shops and restaurants, large recycling companies, clients from international retail chains and many more rely on our solutions.

The company has been run as a family business from the very beginning. A high level of vertical integration and a team of motivated employees ensure a high level of expertise and quality.

Our satisfied customers

Our biggest milestonesFast-forward 70 years of company history

Long-lasting quality from Austria

Years of designing and manufacturing high quality baling presses in Austria. This valid experience ensures reliability, durability and maximum efficiency of all Austropressen products.

Fancy some tech?Join our team!

We are always looking for dedicated people to join our international operating family business.