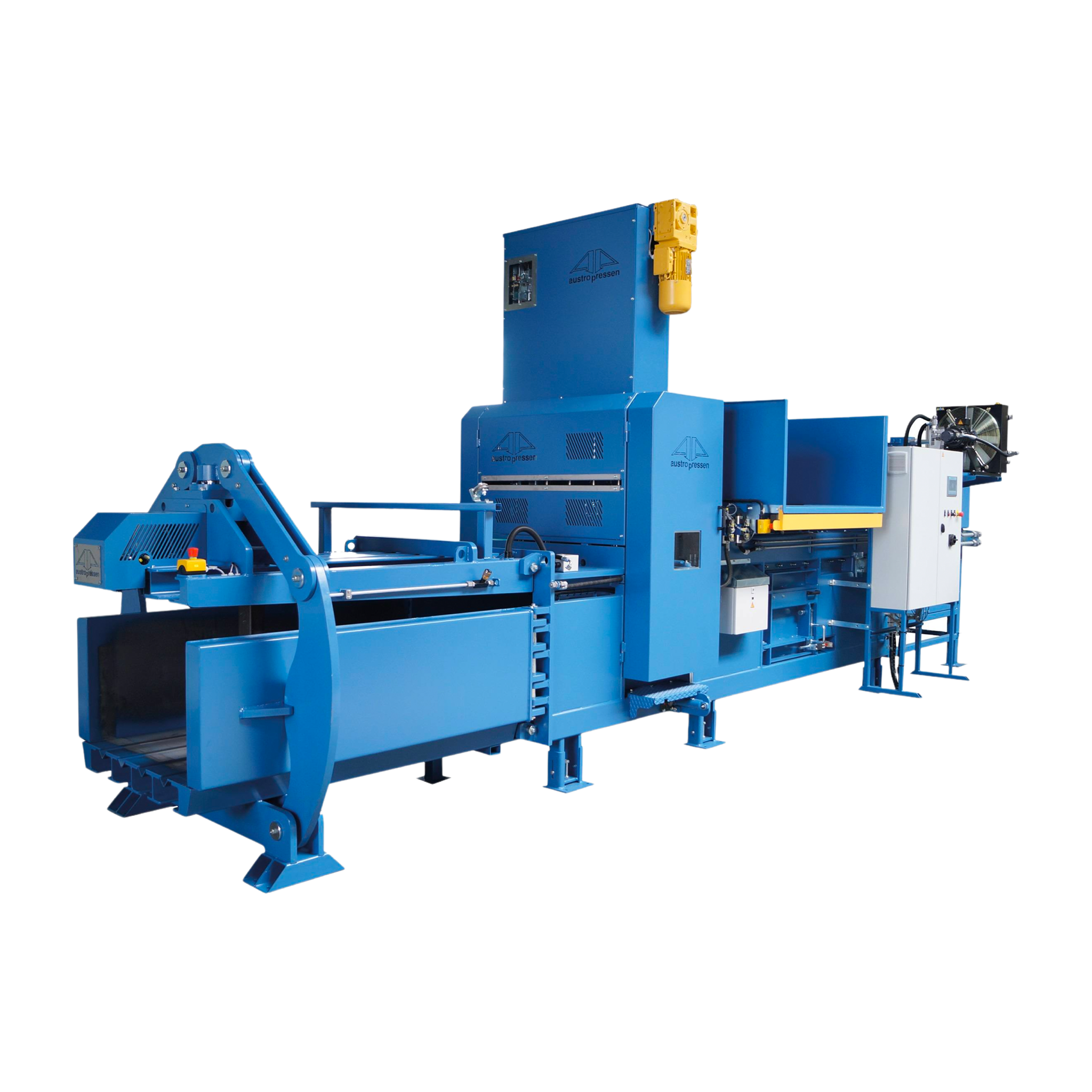

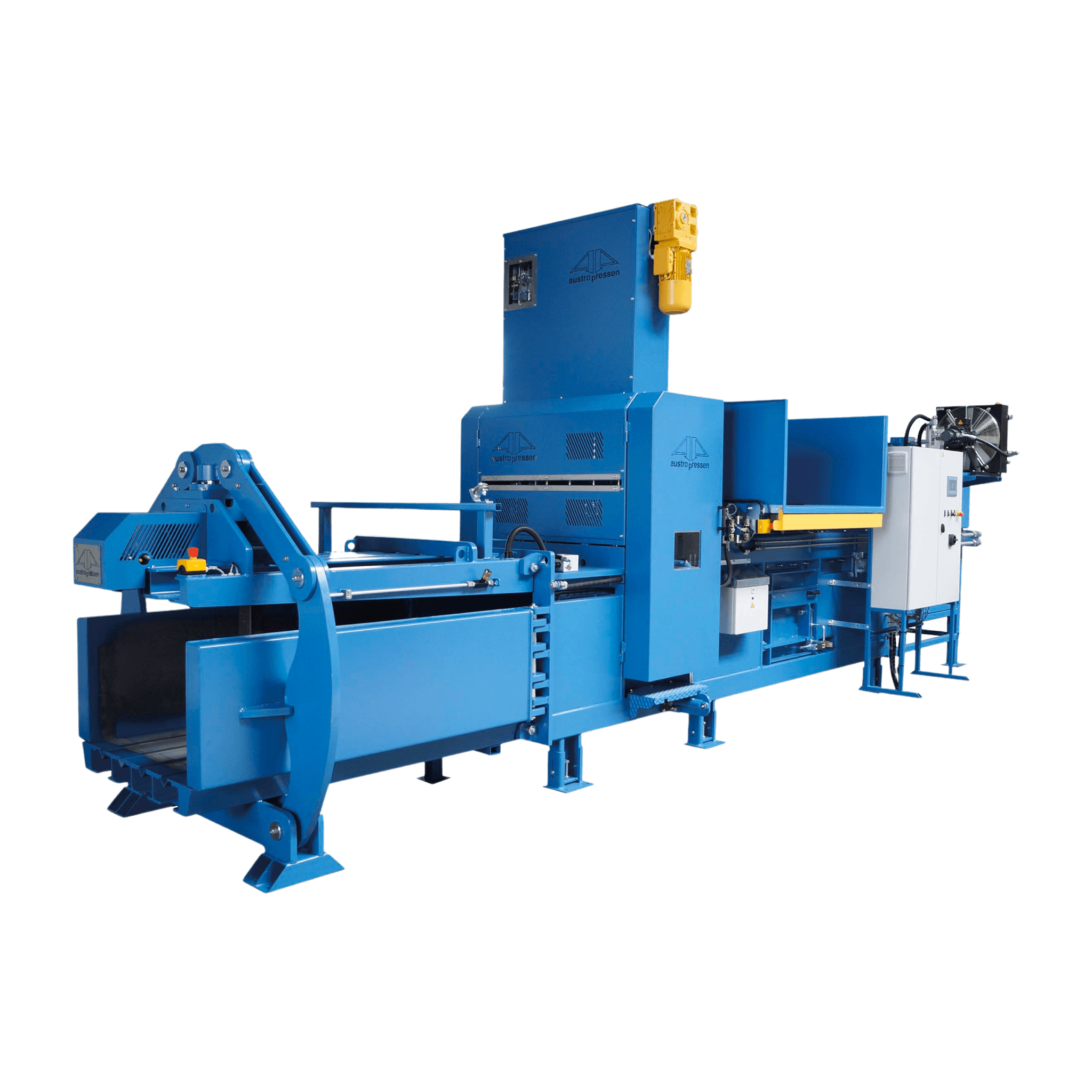

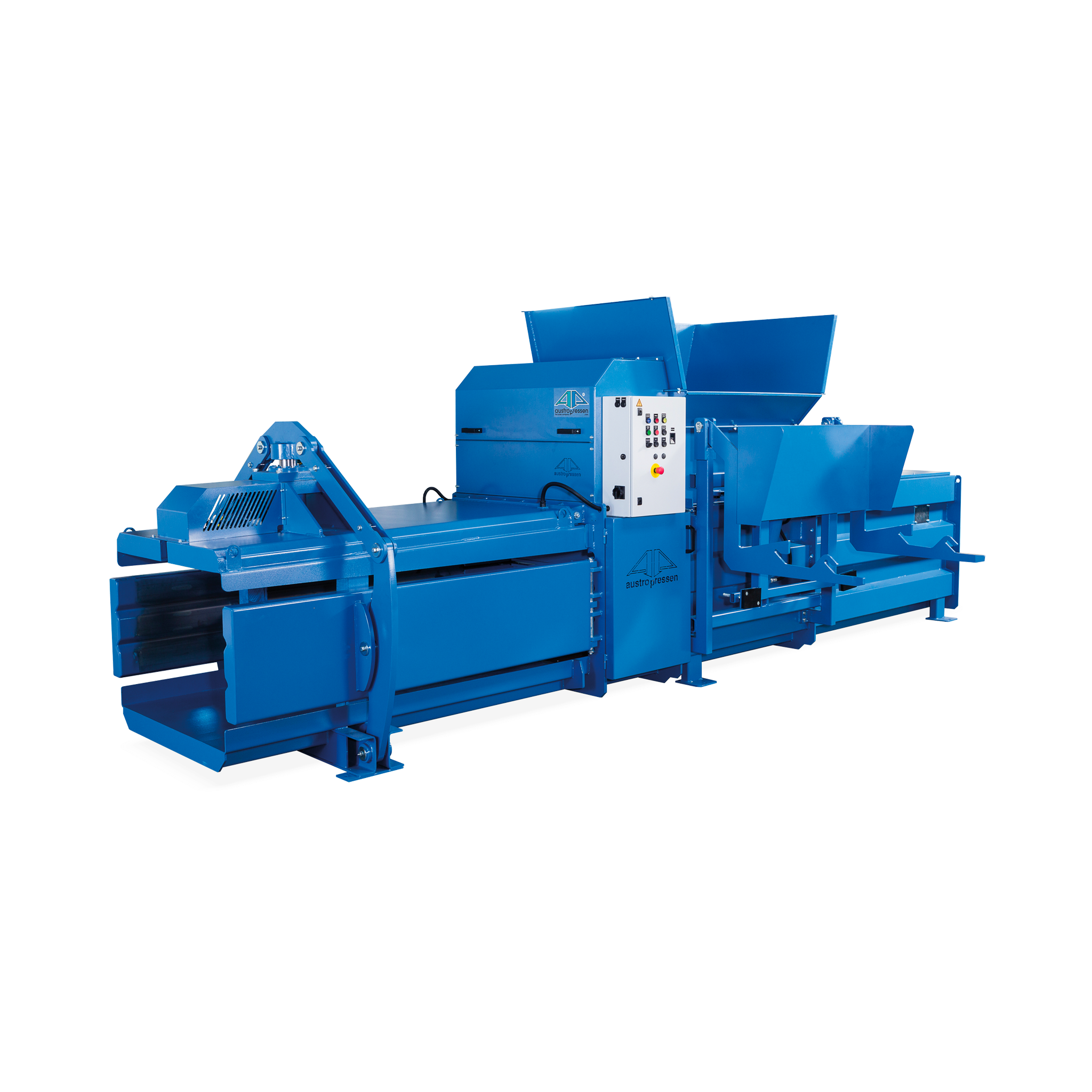

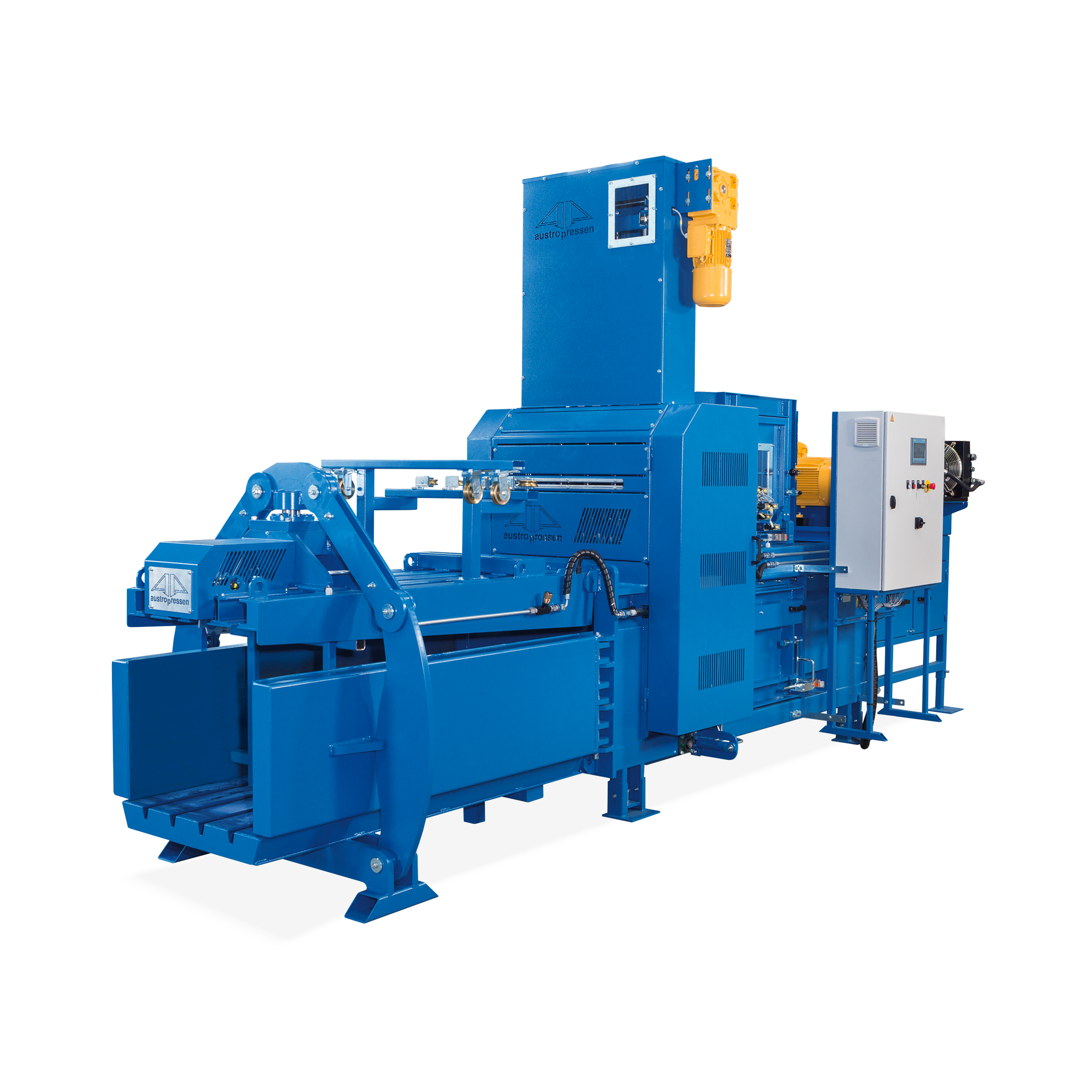

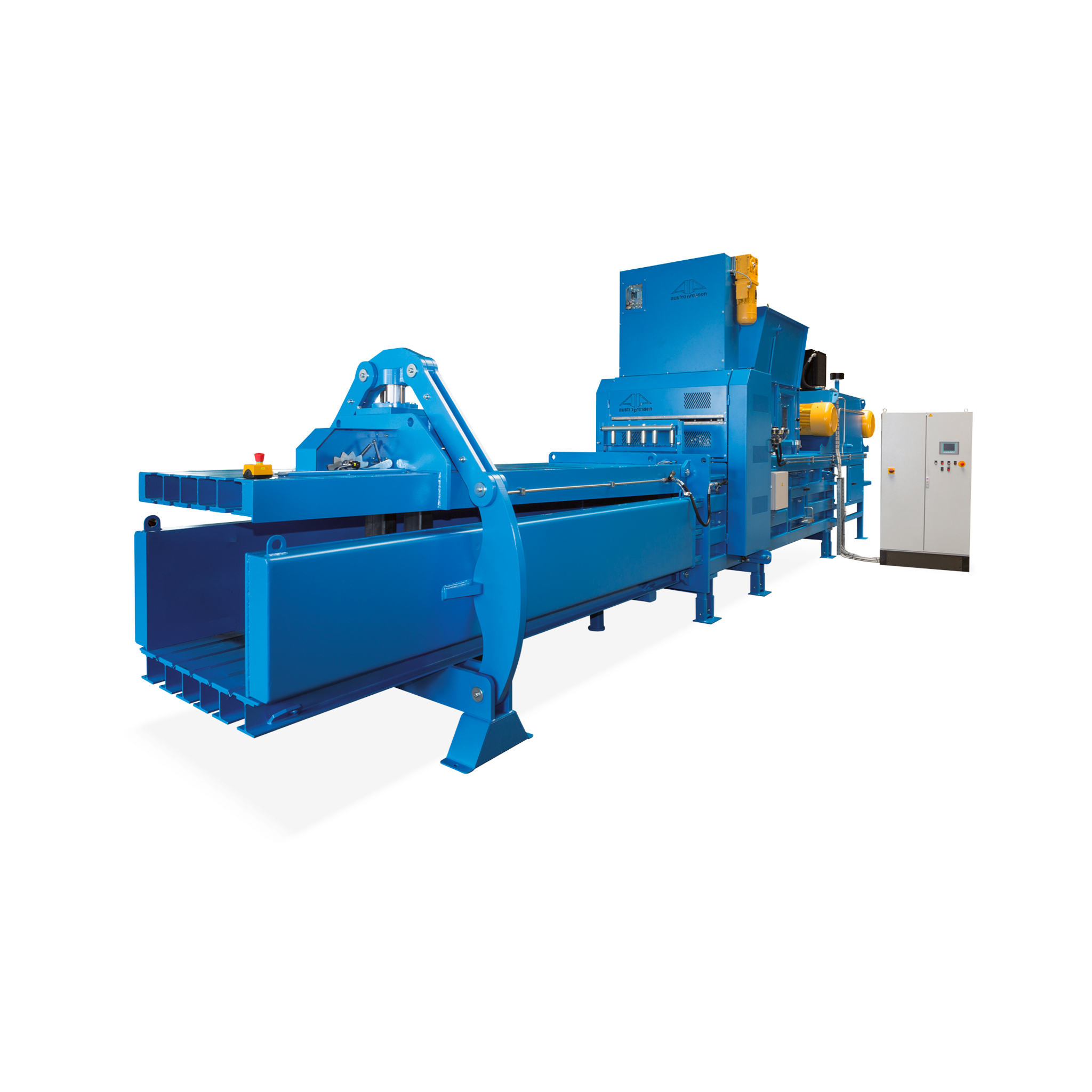

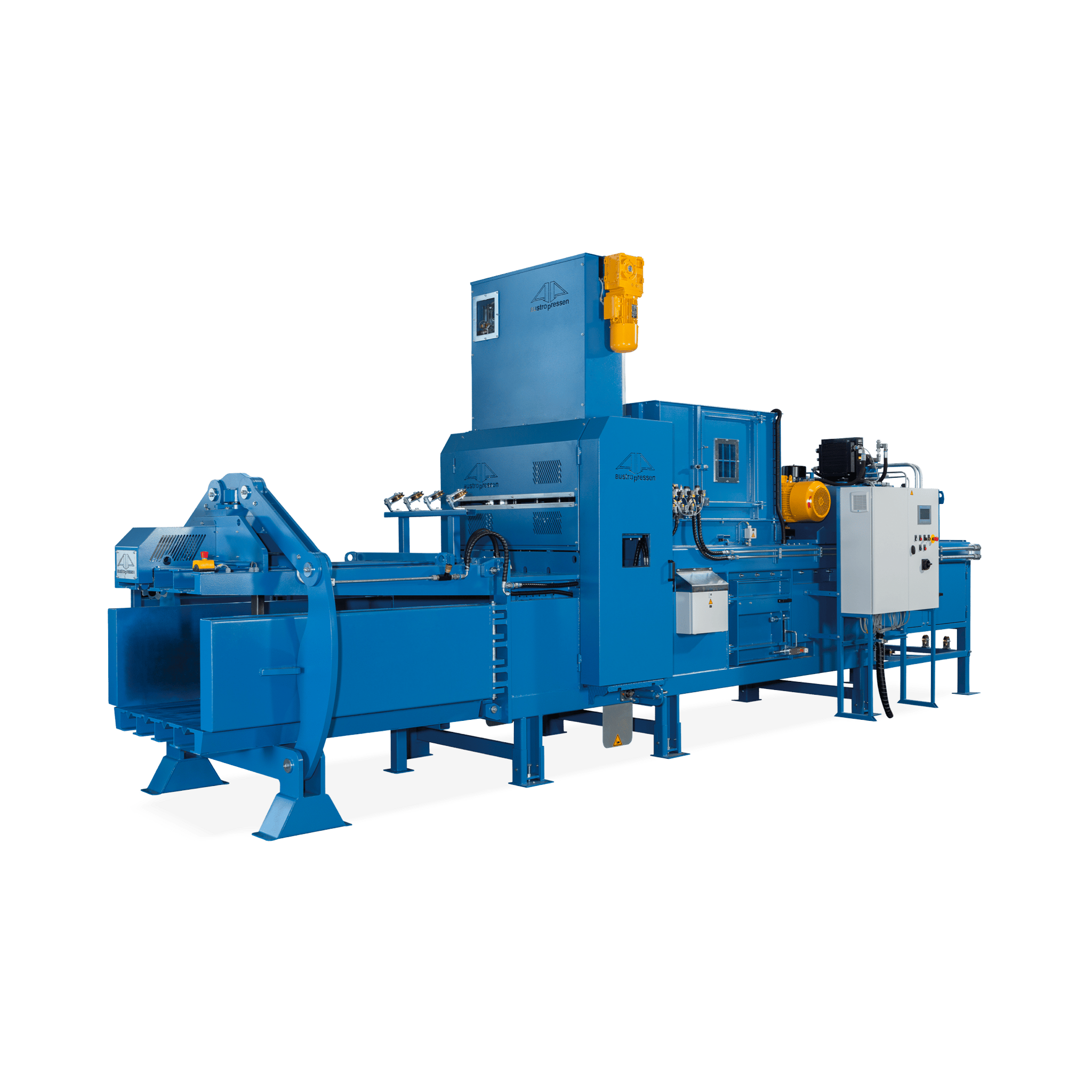

Highly versatile – our all-rounder models

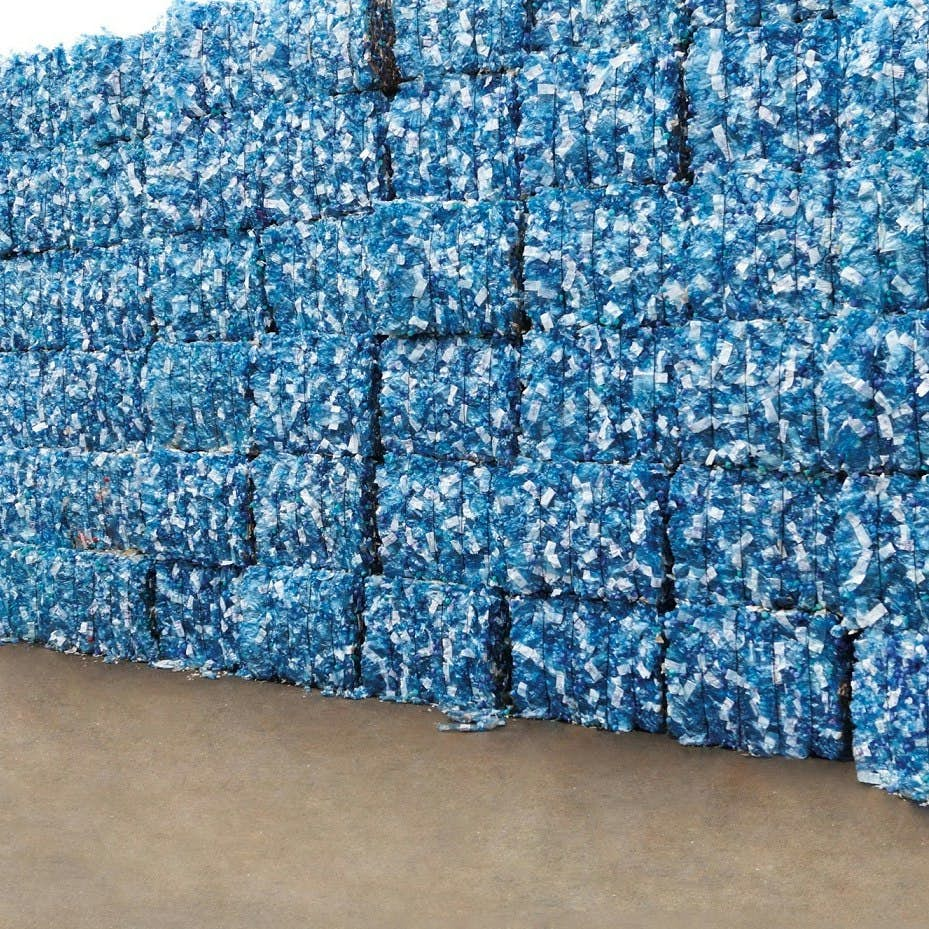

With these newly designed models even experienced users of baling presses are convinced by the high quality and reliability of our industrial balers. Highly compacted bales for an optimal truck loading, high throughput and maximum energy efficiency are the best proof for the excellent efficiency of these channel balers. These continuous, reliable machines in combination with an optimal feeding attachment together provide the modern and future-oriented waste handling for every logistic requirement.

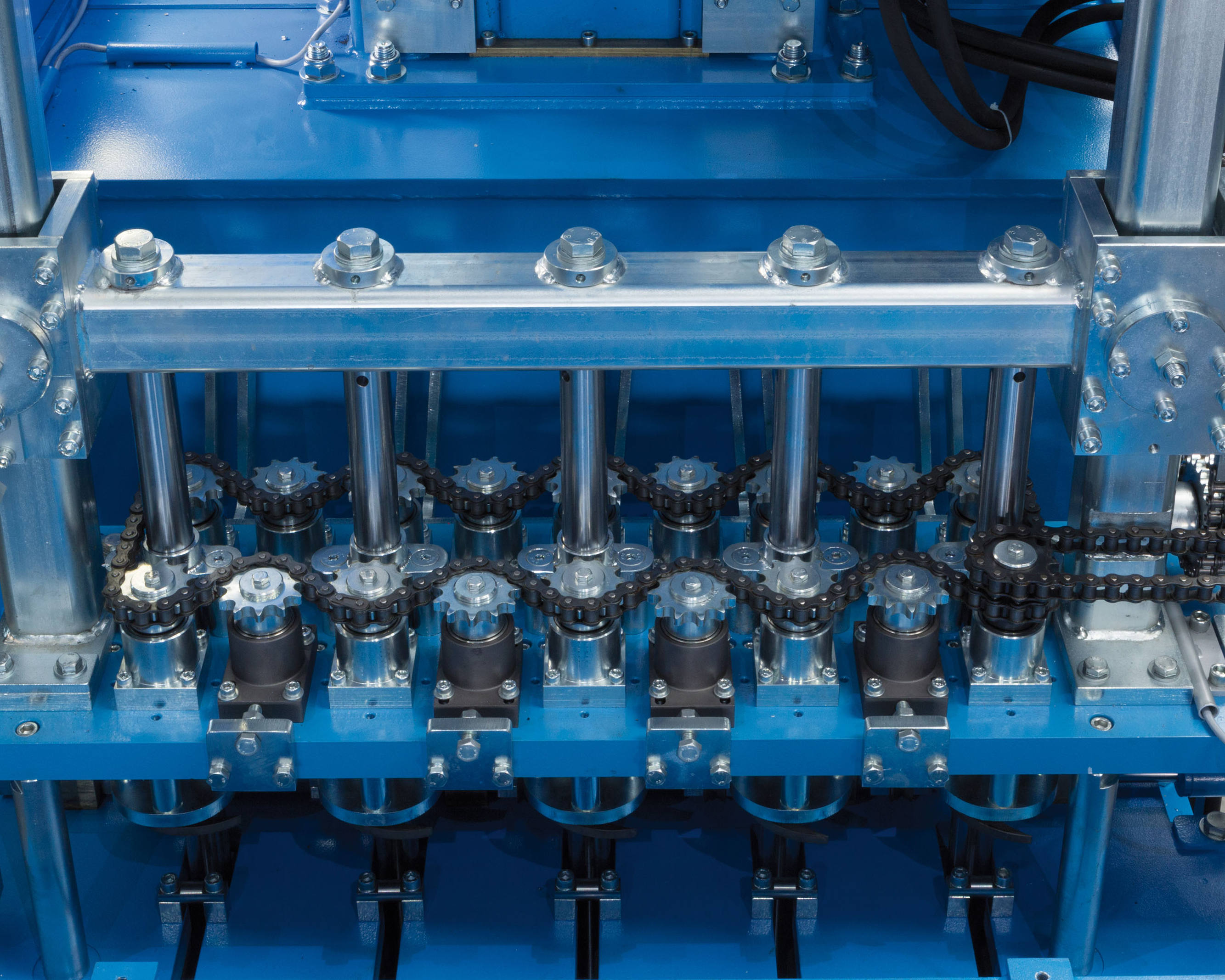

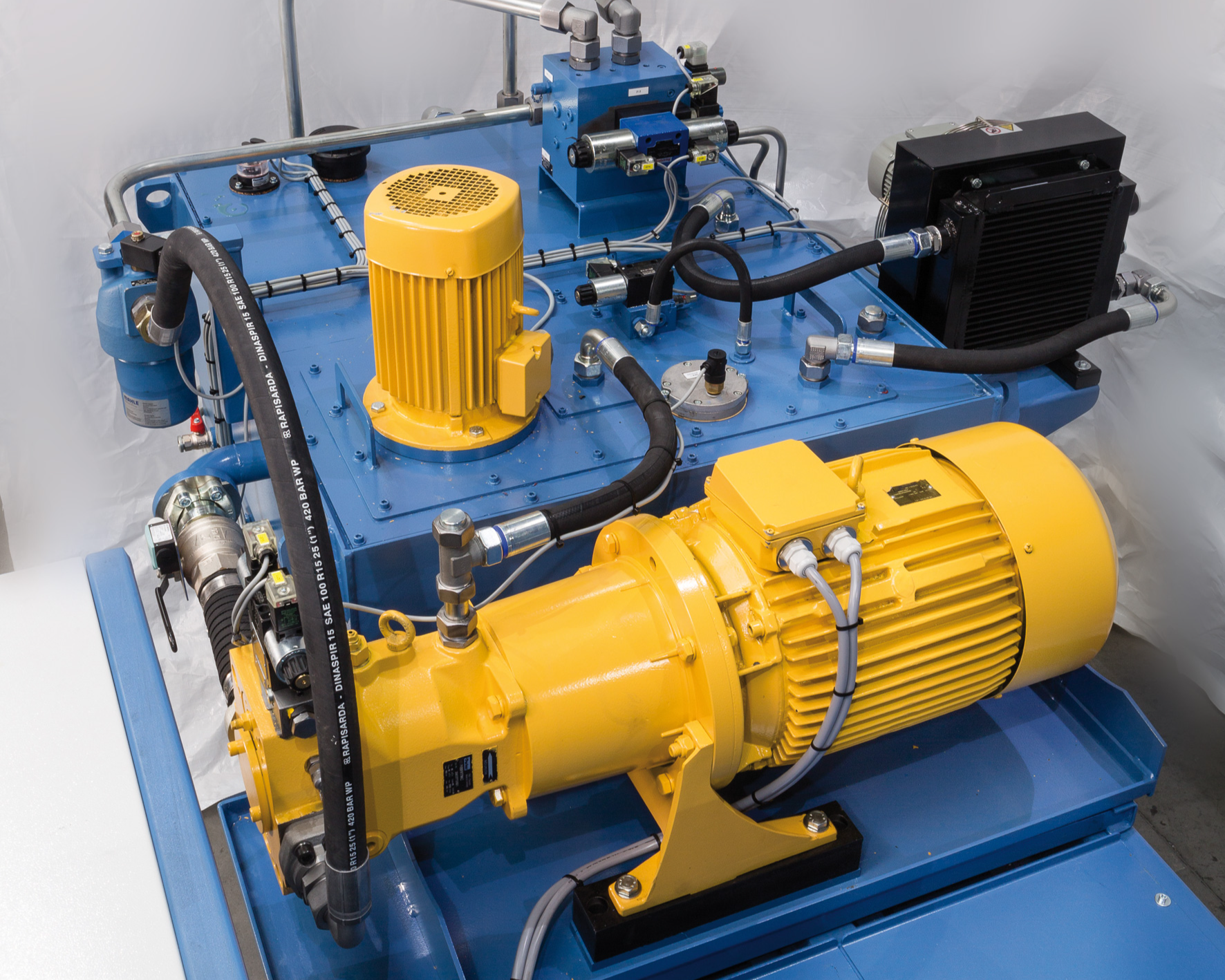

The optimal designed hydraulic blocks, the efficient cutting system and the reliable binding unit DRILLFIX together guarantee maximum throughput and minimum energy consumption.

Models of APK-D series are successfully used in paper industry and packaging production, central storage facilities of the retail sector, logistic and dispatch centers, companies of plastics recycling or in the automotive industry.

APK-D range at a glance: