Concentrated solutions for smart waste management at many VEOLIA locations

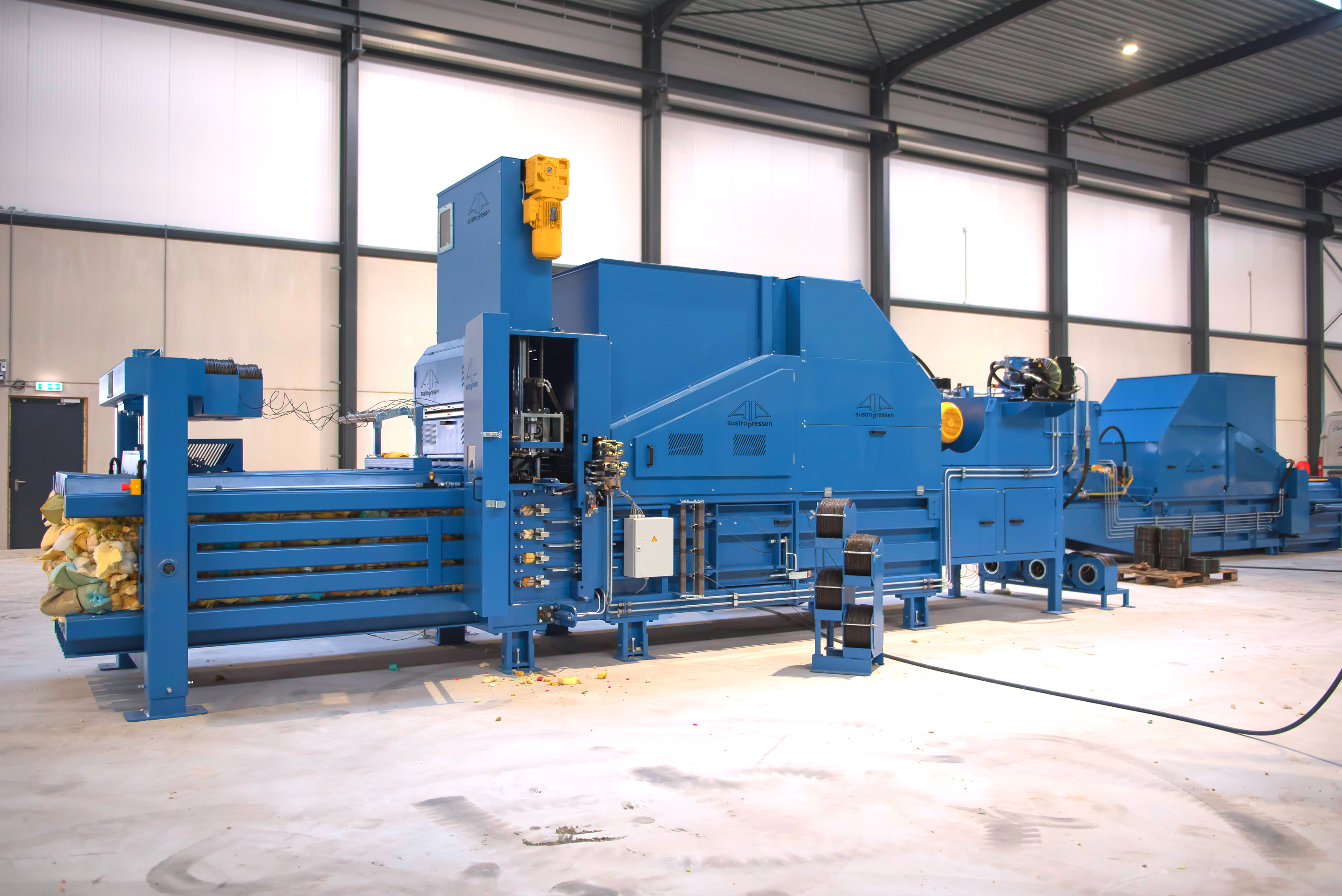

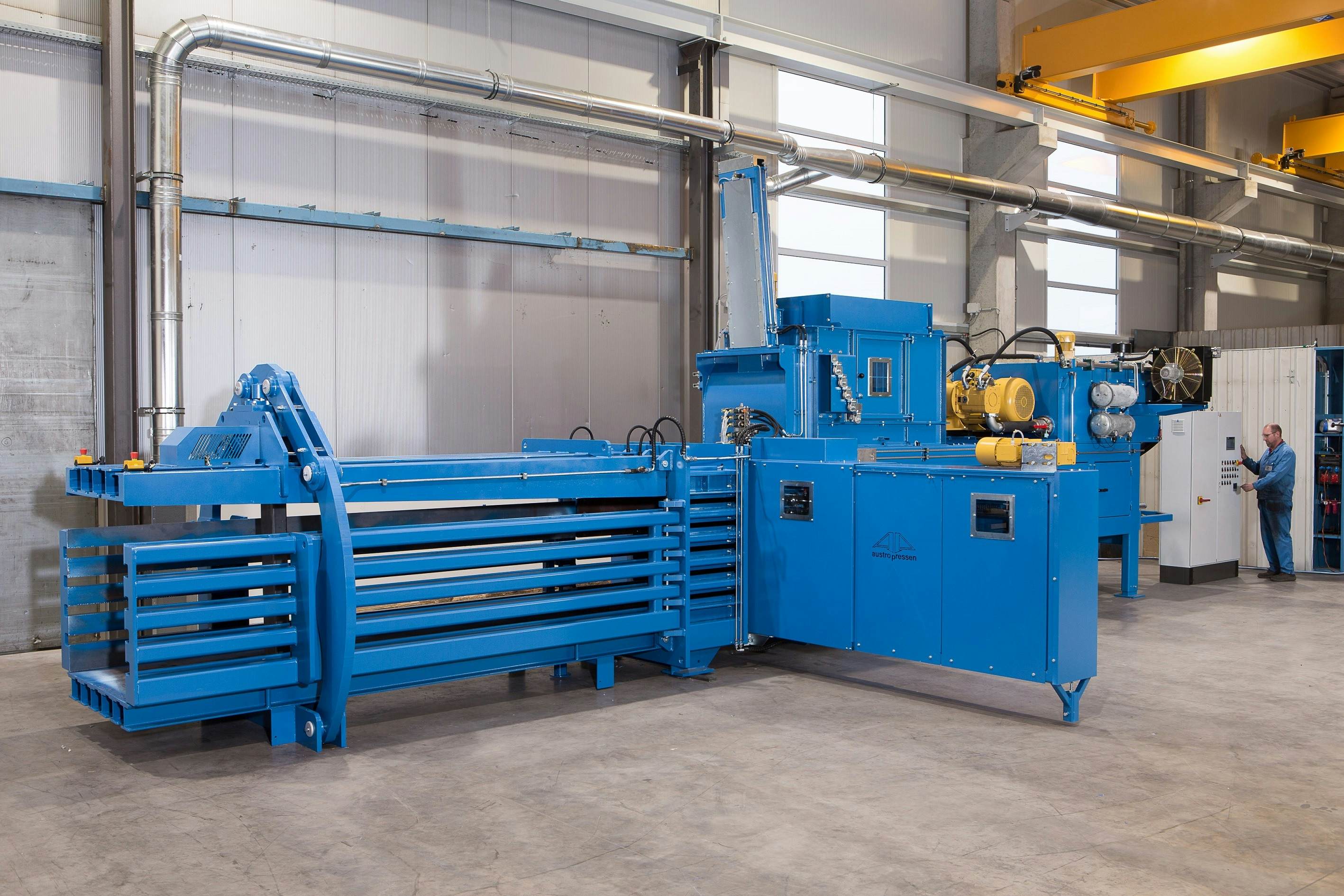

As a major waste management company, Veolia operates its own sorting plants in Germany and manages the waste of major retail chains such as REWE Group. Austropressen's APK channel balers are successfully used at many locations.