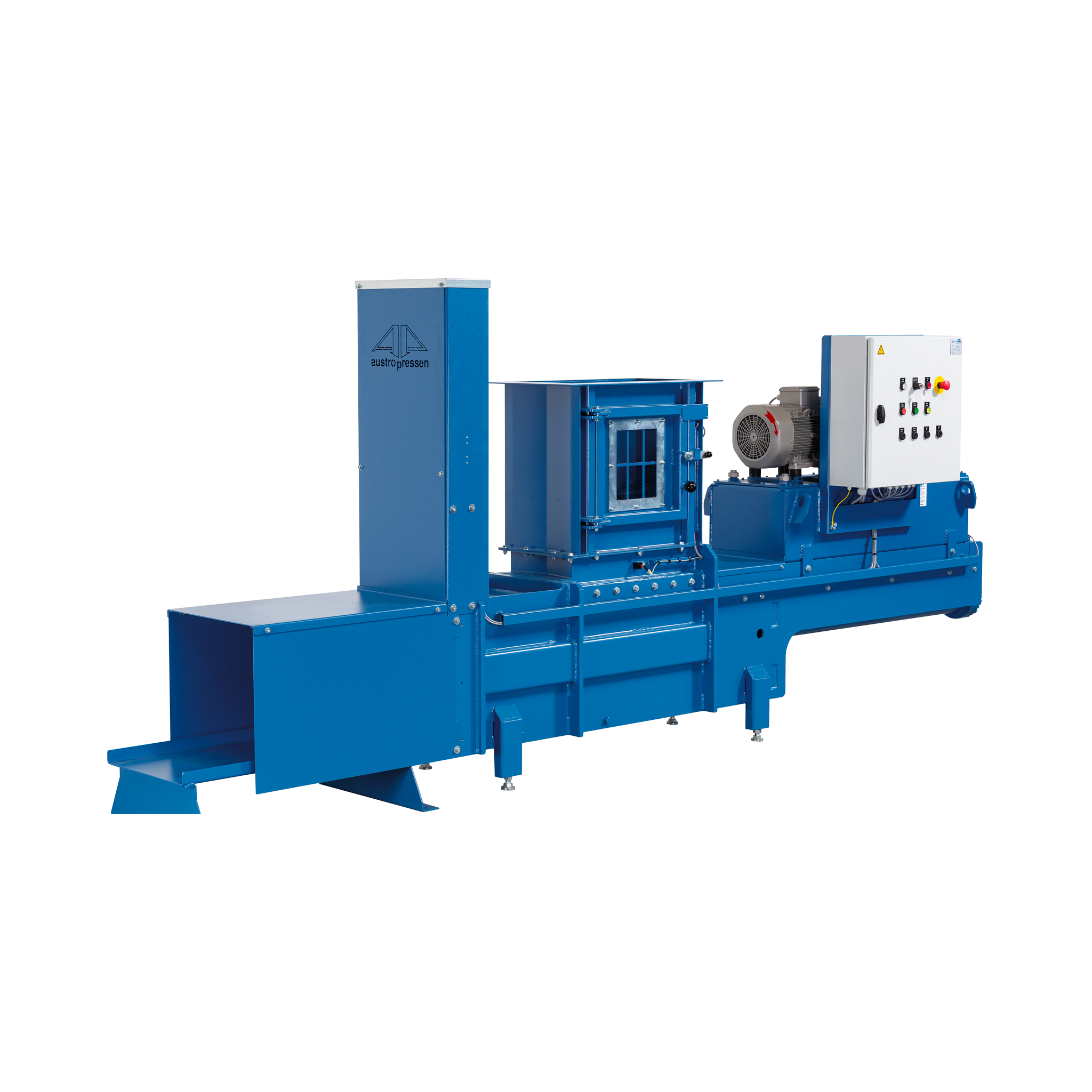

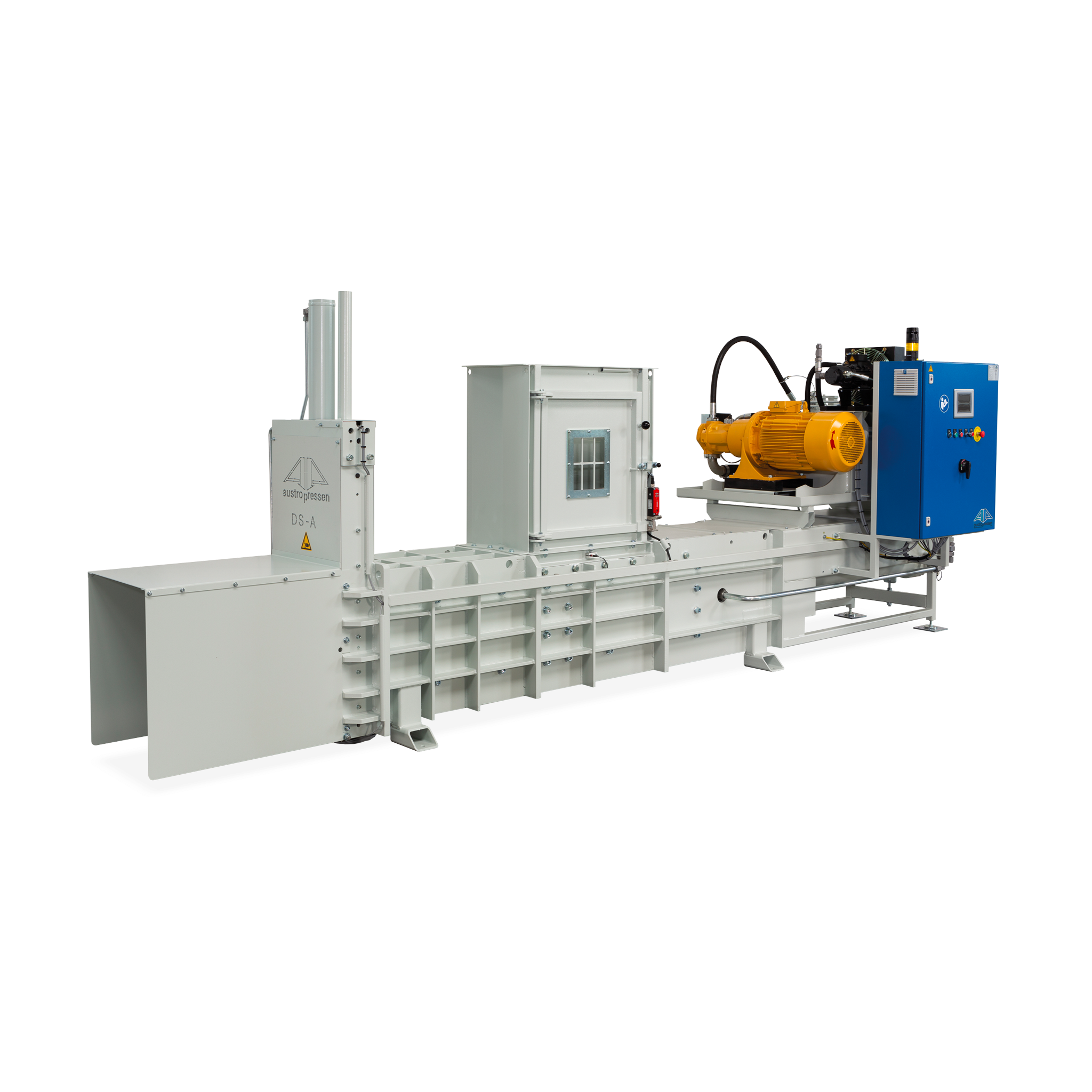

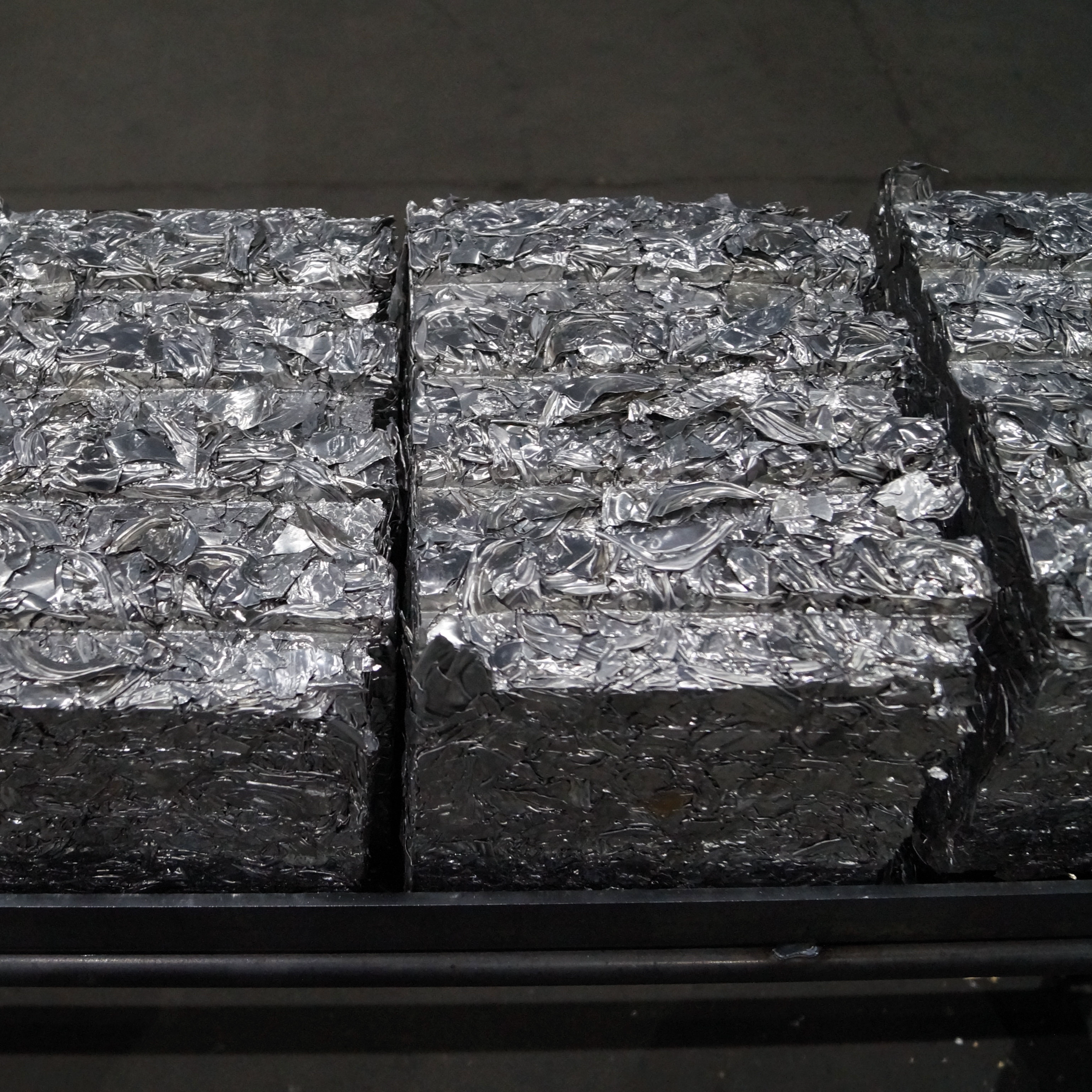

Automatic Scrap Baler DS-A 2200

Compact but powerful scrap balers

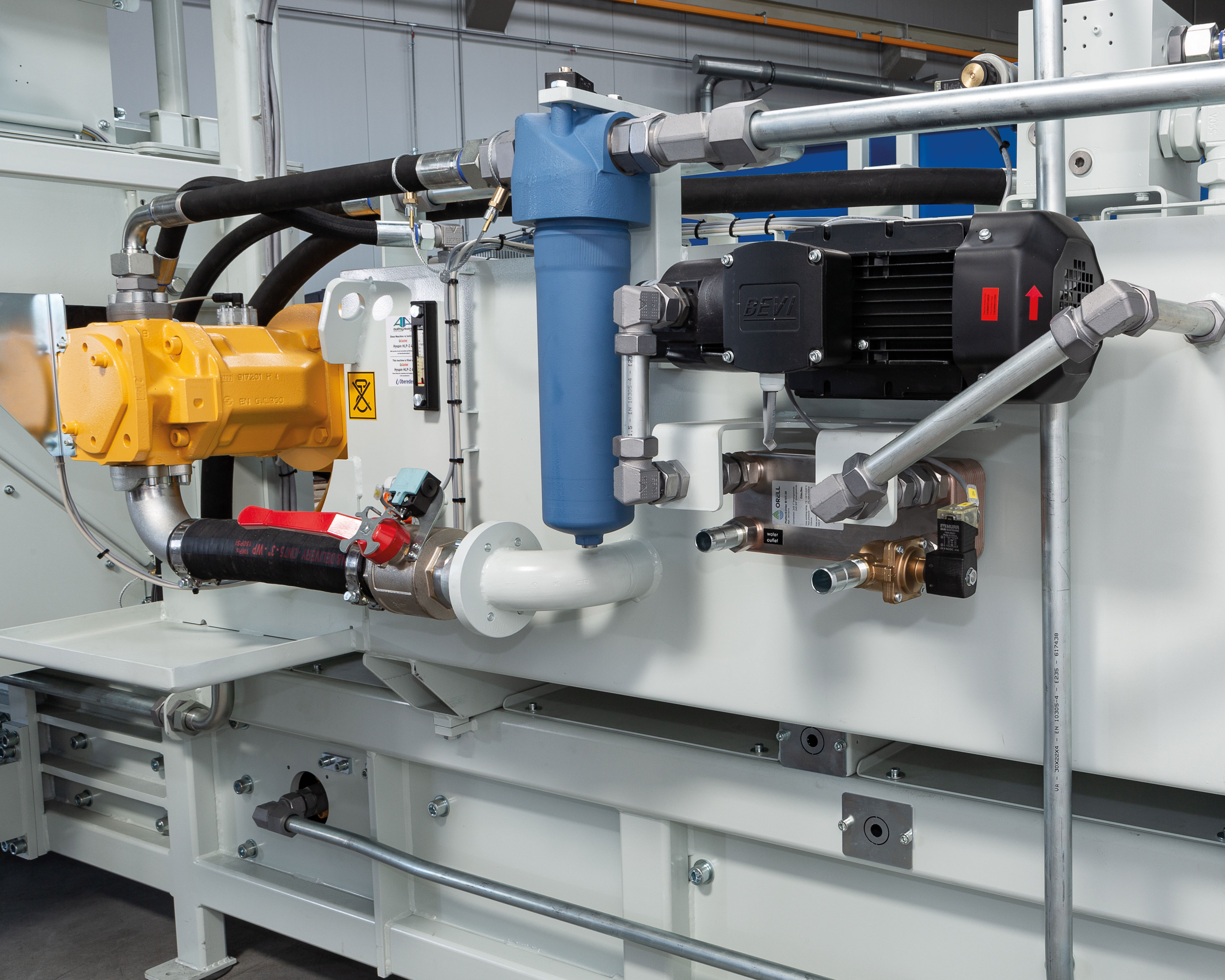

Utilizing the pressure of 4 x separate cylinders each cycle, this newly developed system offers remarkable power of compaction and therefore easily handles even pre-shredded light and little clippings coming from can ends production lines.

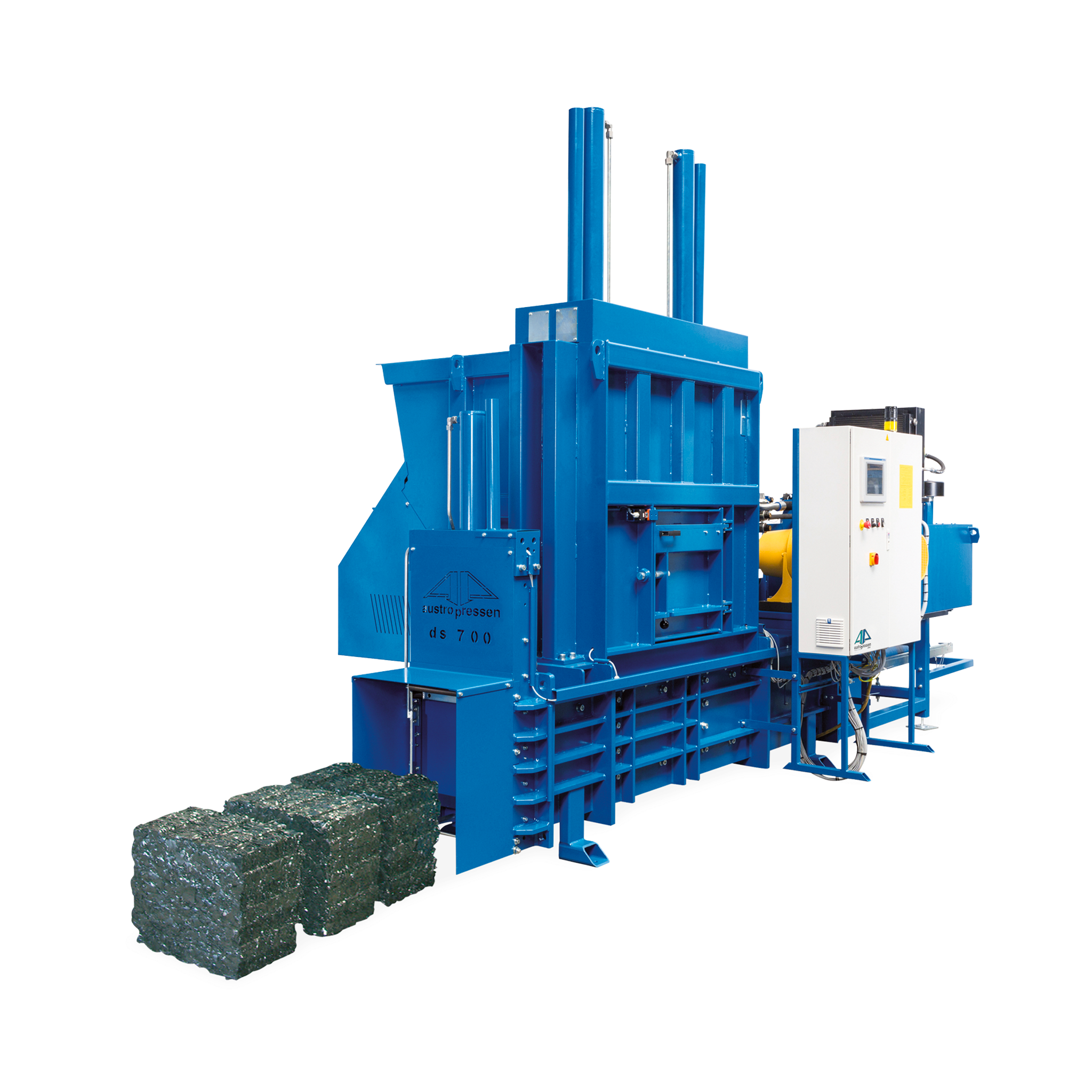

These scrap baler models process up to 1200 kg of aluminum scrap per hour at a bale density of max. 1100 kg/m³.

The main benefits:

Data monitoring like quality of bales as well as energy consumption via PLC

Easy and cost-effective remote technical support

High energy efficiency due to use of innovative technologies

High density, stackable bales of up to 18 kg per minute

Categories

Automatic Scrap Metal BalersMaterials

MetalsNaN/undefined

Fully automatic and continuous operation

Maximum ease of use and maximum operator safety

Highly wear resistant and low-maintenance

High durability due to replaceable HARDOX wear plates

Data monitoring like quality of bales as well as energy consumption via PLC

Optionally expandable by data highway or remote monitoring tools

Easy and cost-effective remote technical support

High energy efficiency due to use of innovative technologies

High durability and reliability based on our quality standards

- ModelleDS-A-2200

- Press load2200 kN

- Specific press load3700 N/cm²

- Driver power45 kW

- Moudling cycle70 sec

- Theoretical throughput35 m³/h

- Bale format (LxB)290x230x130-160 mm

- Dimensions (LxBxH)5200x2250x2750 mm

- Weight8400 kg

All models and full technical data:

Easily handles even pre-shredded light and little clippings coming from can ends production lines. These baler models process up to 1200 kg of aluminum scrap per hour at a bale density of max. 1100 kg/m³.

Further products

Long-lasting quality from Austria

Years of designing and manufacturing high quality baling presses in Austria. This valid experience ensures reliability, durability and maximum efficiency of all Austropressen products.