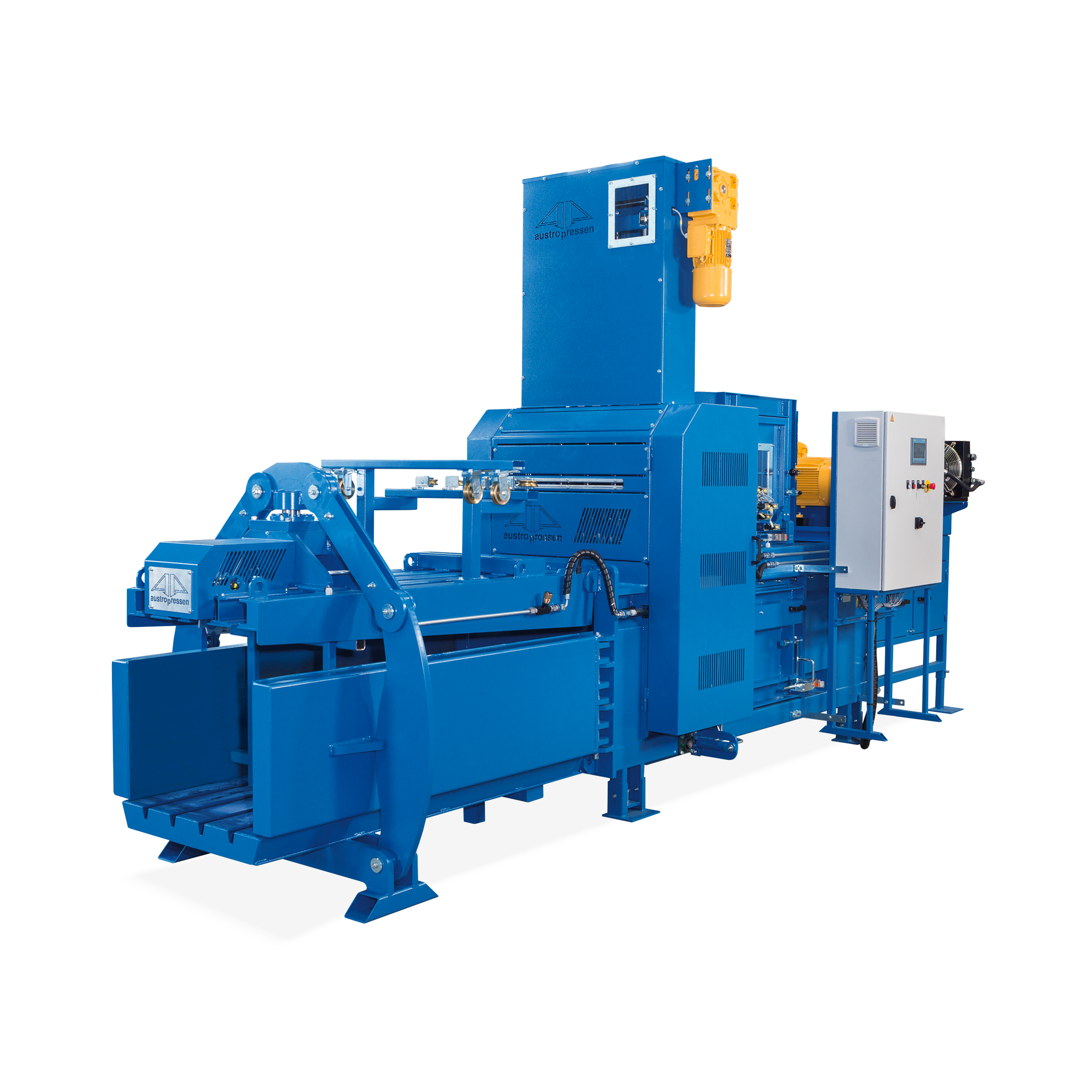

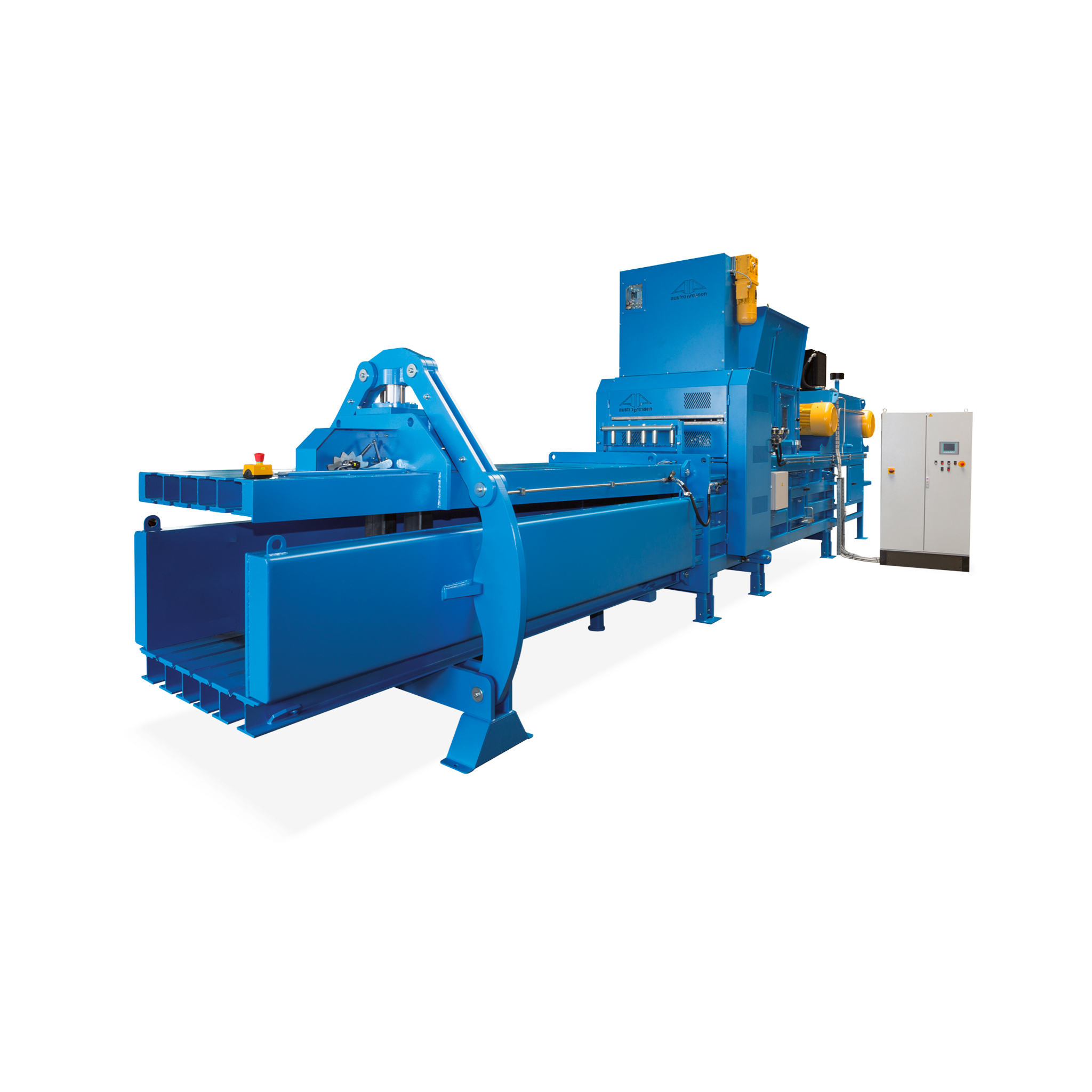

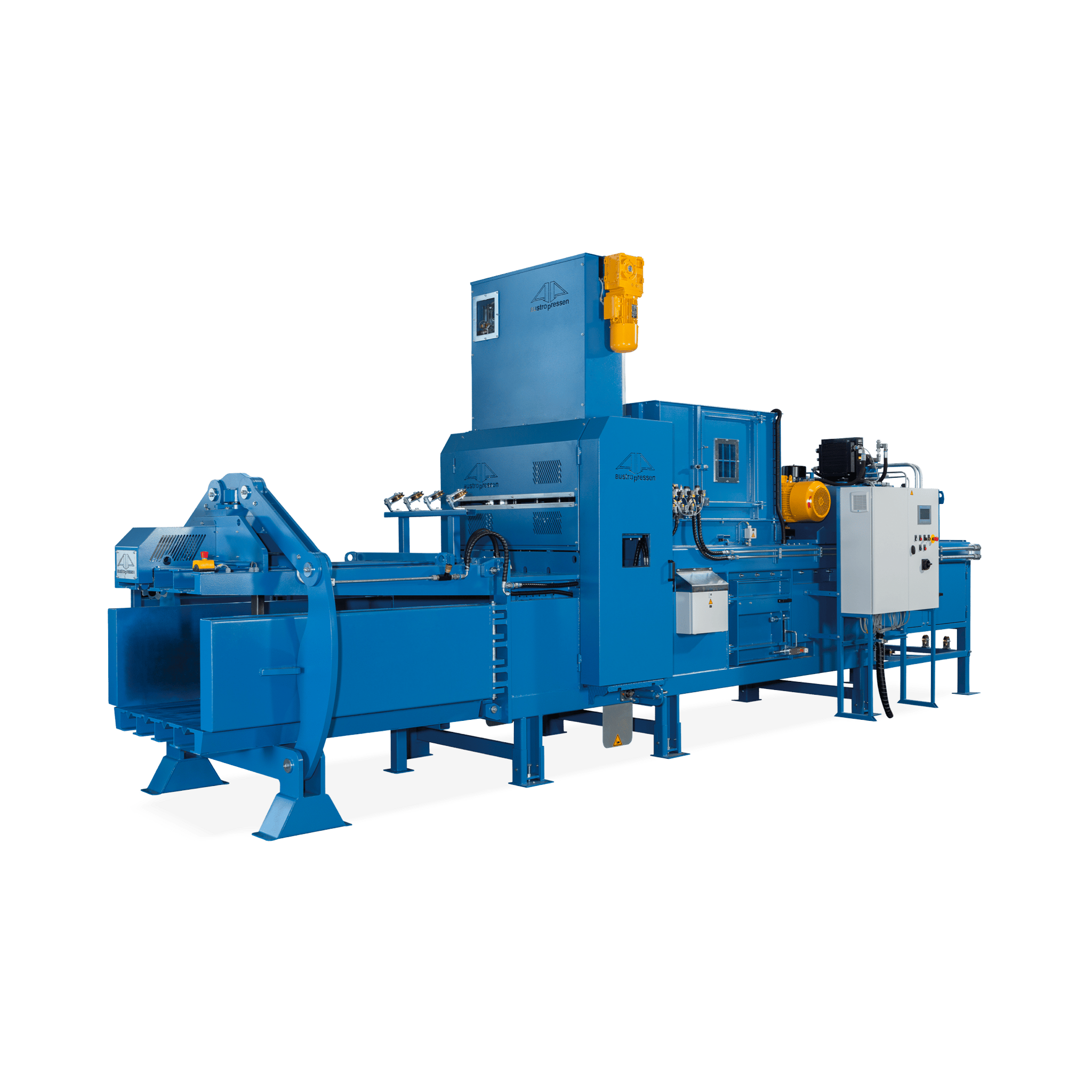

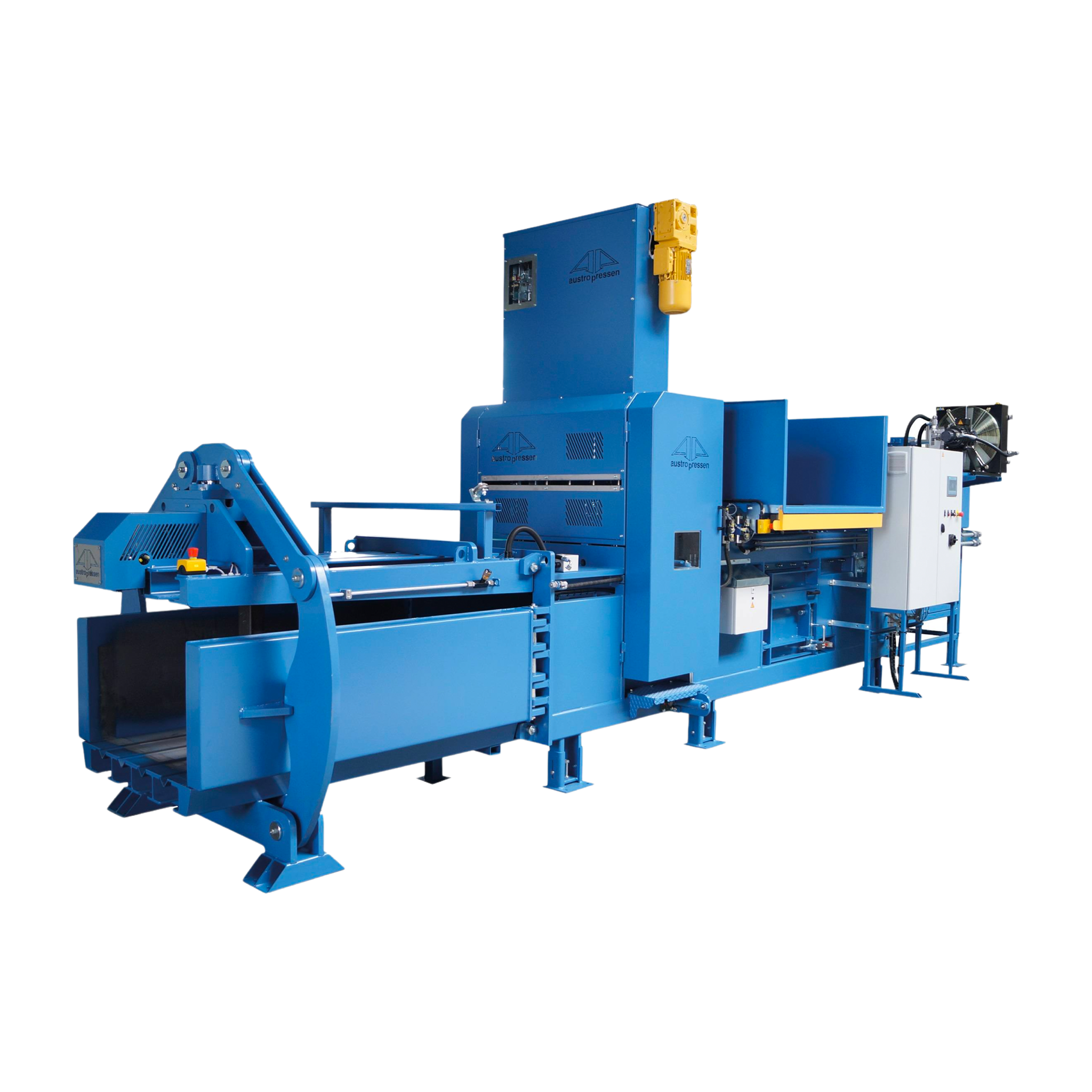

Semi-automatic Channel Baler AP-SK 12

High operating & energy efficiency

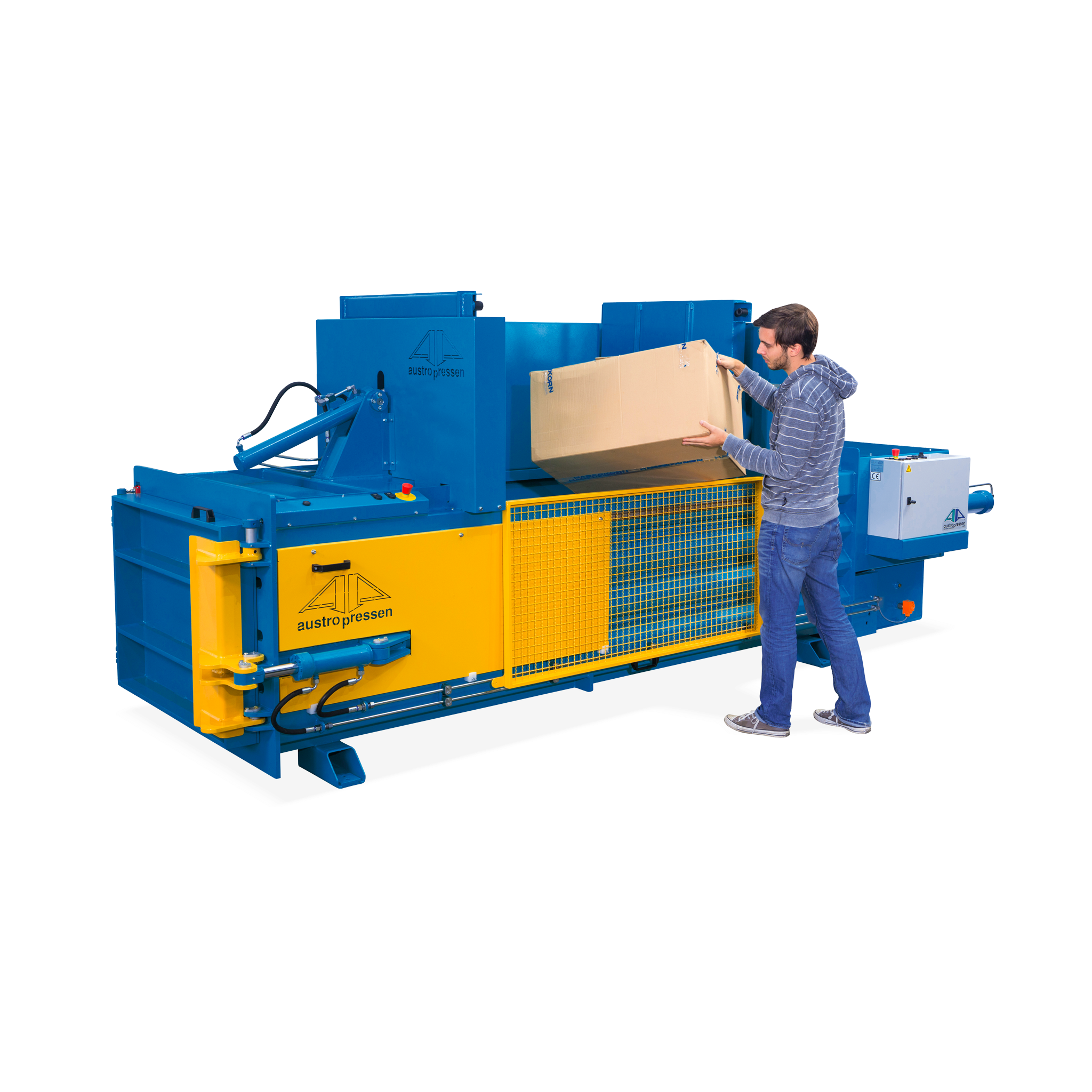

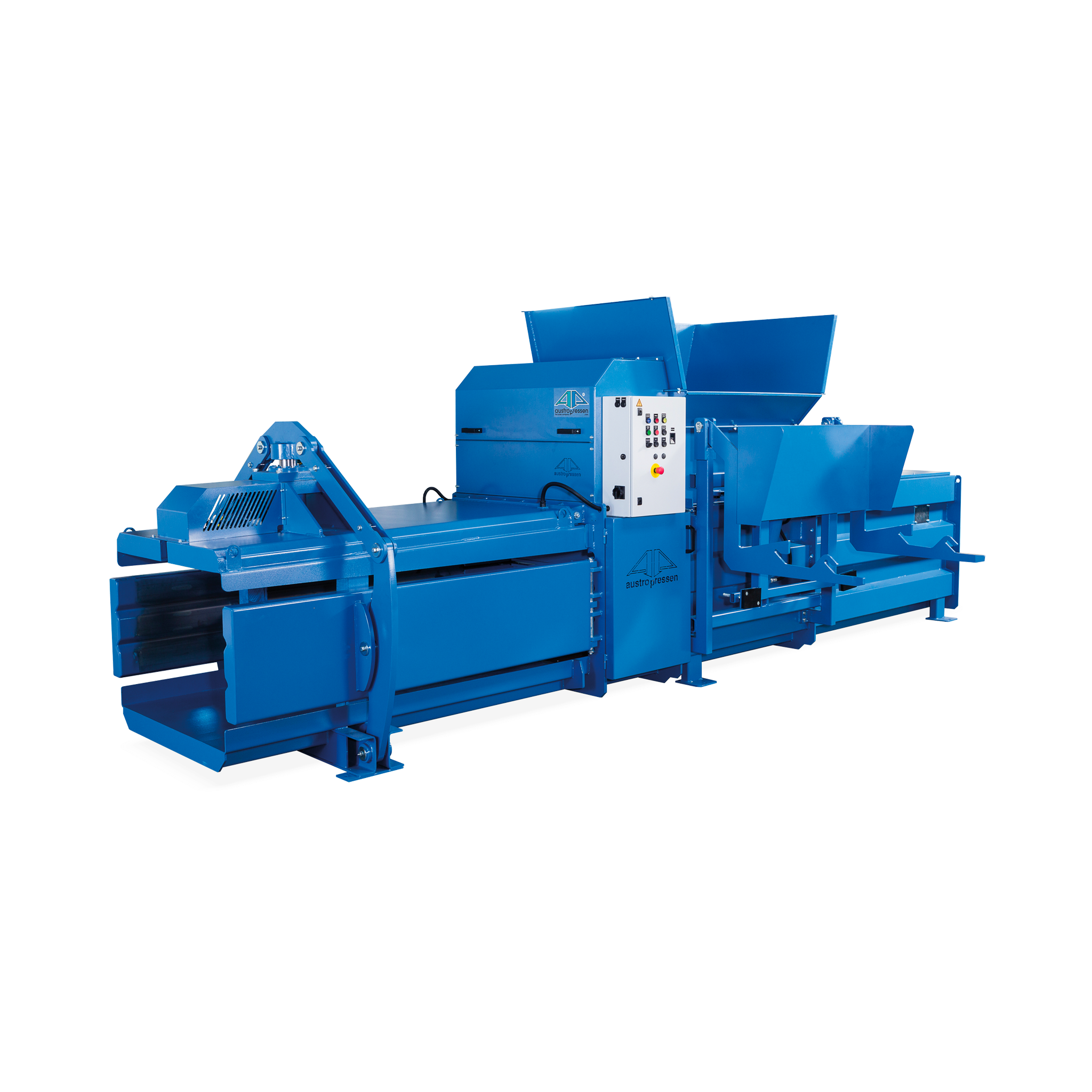

Models of the series AP-SK from Austropressen are semiautomatic channel baling presses. The continuously operating machines in combination with suitable feeding system result in modern cost-effective waste handling. Therefore, the optimal solution for industry and warehouses for compaction of cardboard and plastic film.

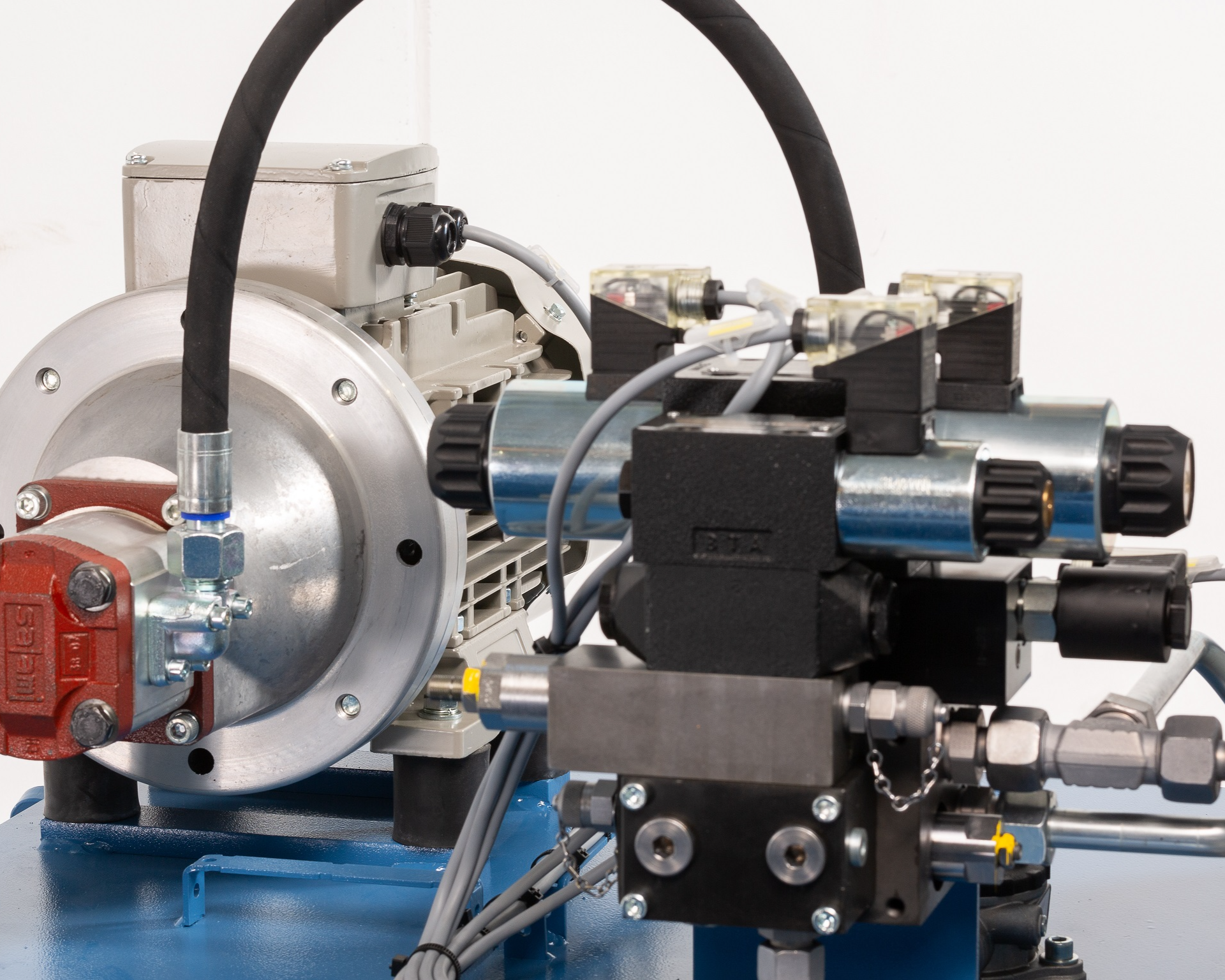

Optimally dimensioned hydraulic units in combination with the patented cylinder system ensure efficient energy use and low hydraulic oil consumption.

The main benefits:

Remarkable throughput performance

Troublefree continuous operation

Efficient cutting system

Energy-saving hydraulic equipment

NaN/undefined

Efficient cutting unit guarantees a continuous feeding and troublefree operation

Maximum ease of operation at the touch of a button

High level of automation and remarkable throughput performance

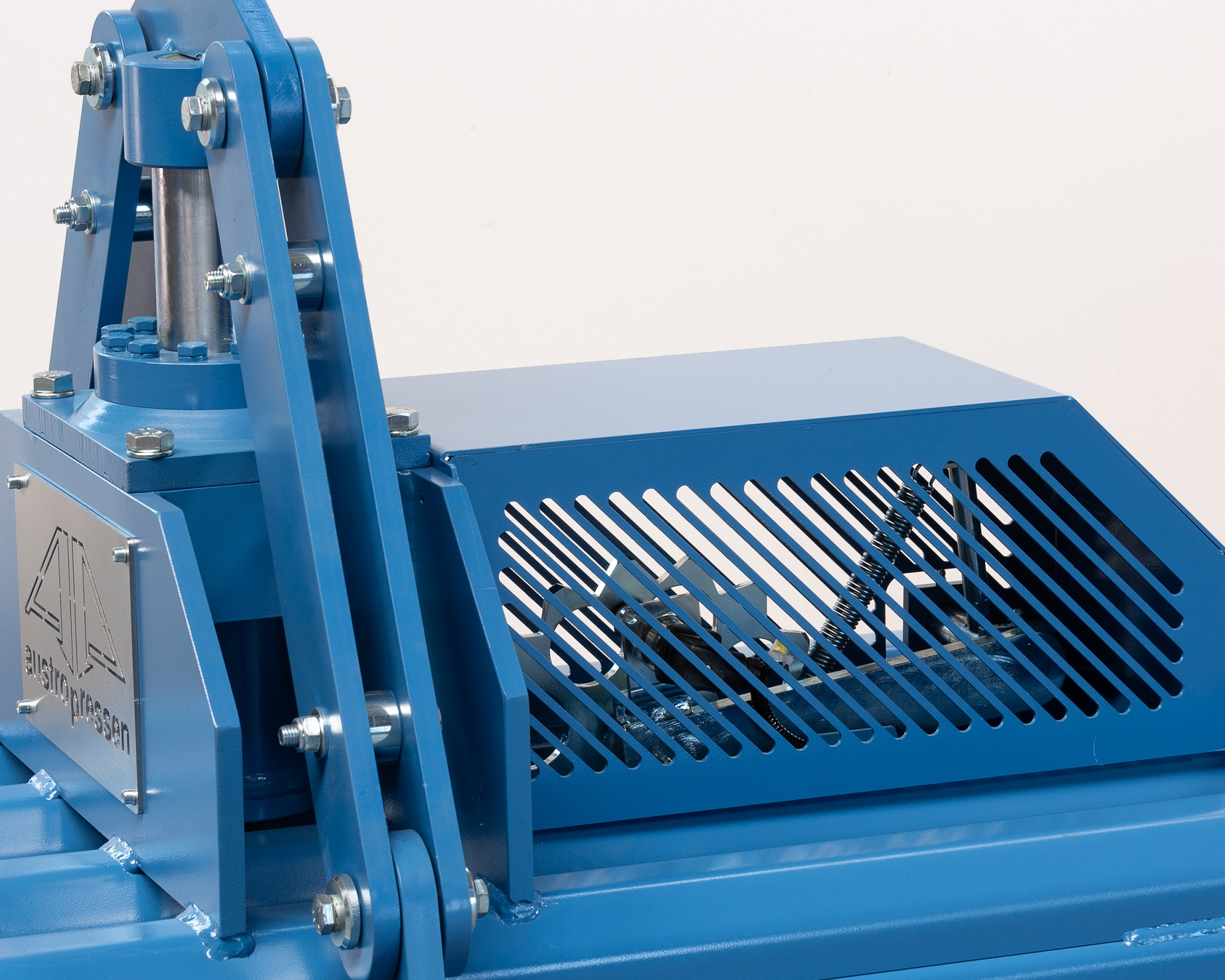

Patented cylinder and hydraulics system ensure efficient energy use and low hydraulic oil consumption

Bale length is adjustable

Multiple binding with wire or plastic strapping tape

Automatic, pressure-controlled channel regulation on three sides

Additional equipment available - f.ex.. functional tipping device

High durability and reliability based on our Austropressen quality standards

- ModelleAP-SK 12

- Press load120 kN

- Specific press load40 N/cm²

- Driver power4 kW

- Moudling cycle50 sec

- Theoretical throughput15 m³/h

- Filling hatch (LxB)600x540 mm

- Filling height1260 mm

- Bale format (LxB)600x500 mm

- Bale length600- 1200 mm

- Bale weight100- 120 kg

- Dimensions (LxBxH)3900x1200x1600 mm

- Weight1950 kg

All models and full technical data:

Optimal solution for industry and warehouses for compaction of cardboard and plastic film.

Further products

Long-lasting quality from Austria

Moren than 50 years of designing and manufacturing high quality baling presses in Austria. This valid experience ensures reliability, durability and maximum efficiency of all Austropressen products.