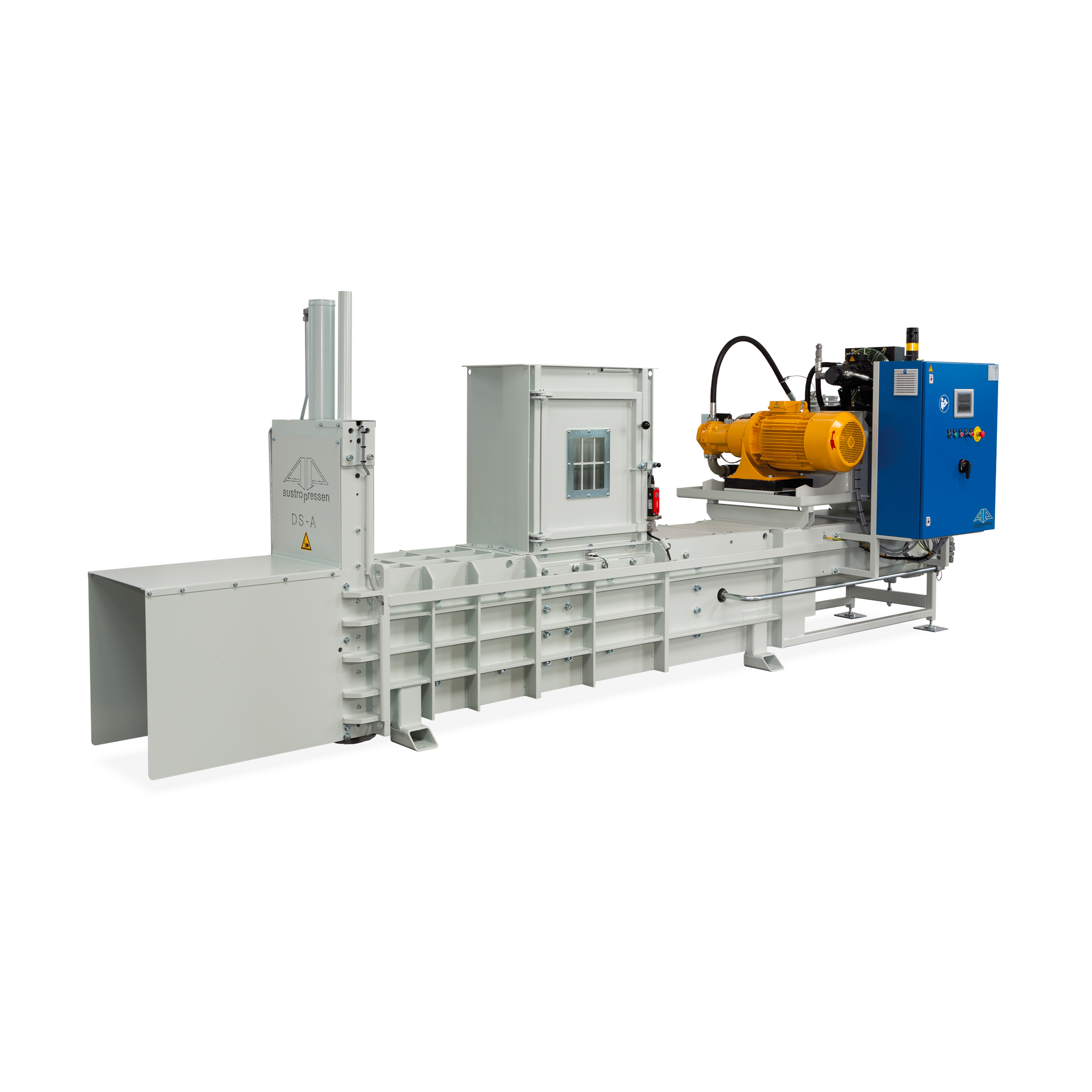

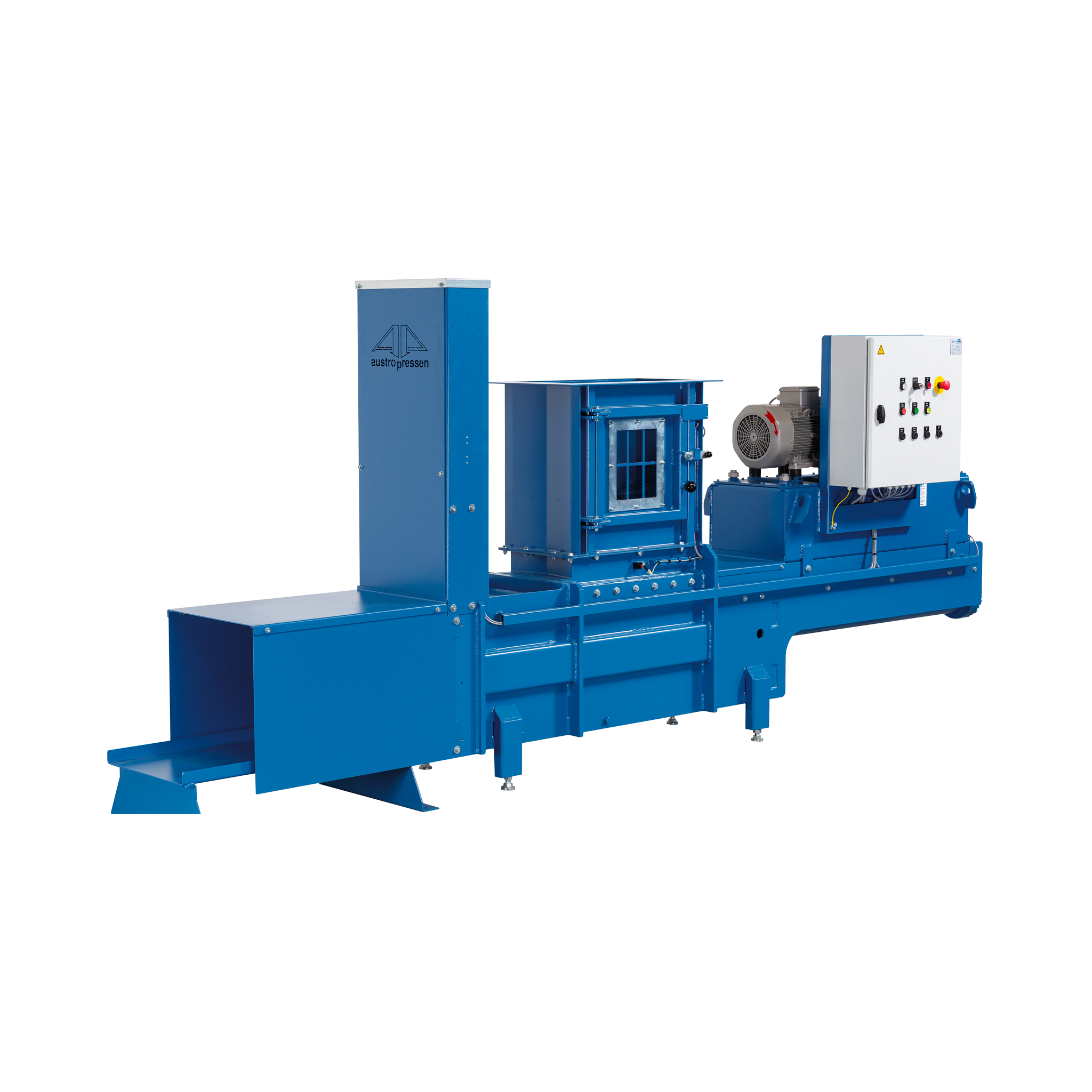

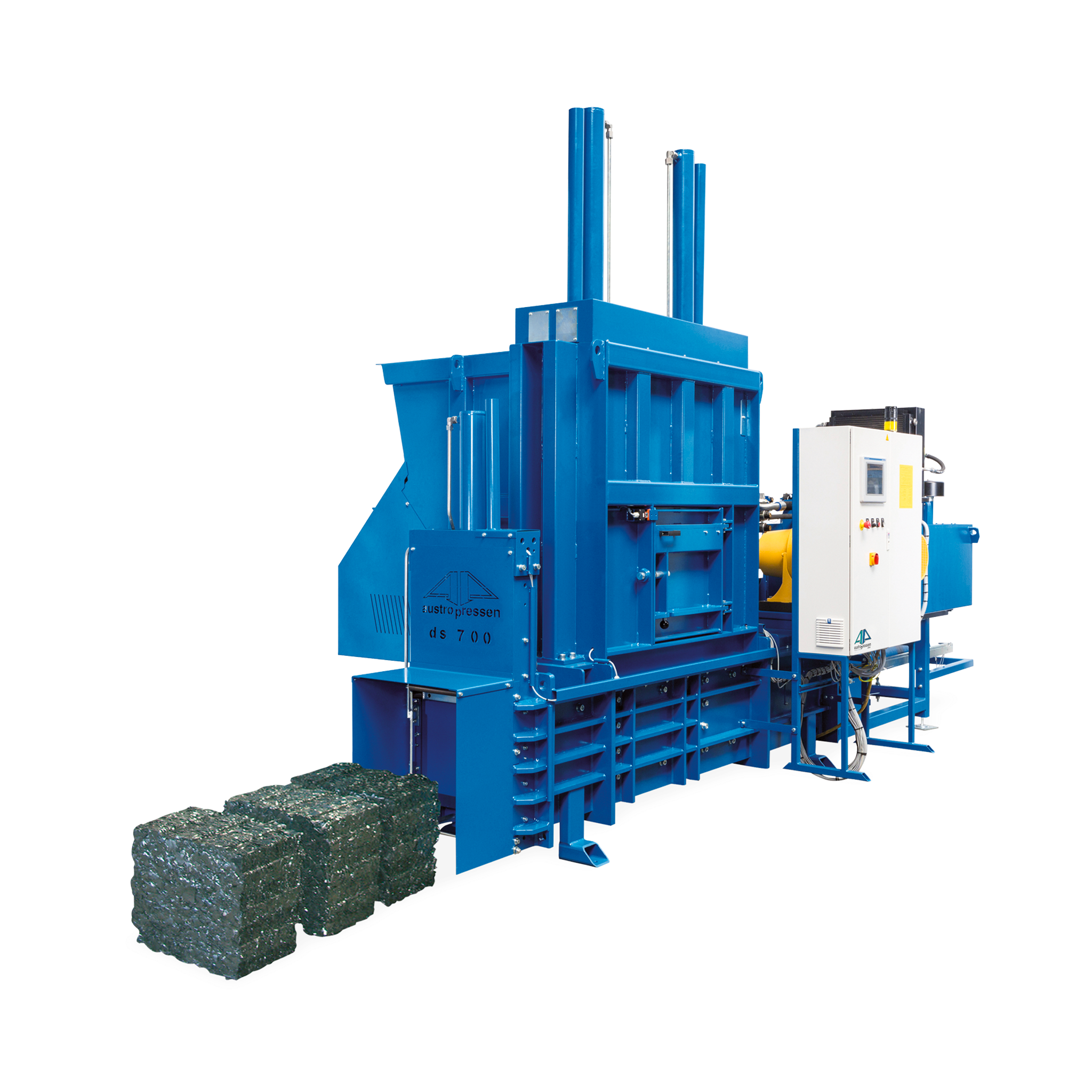

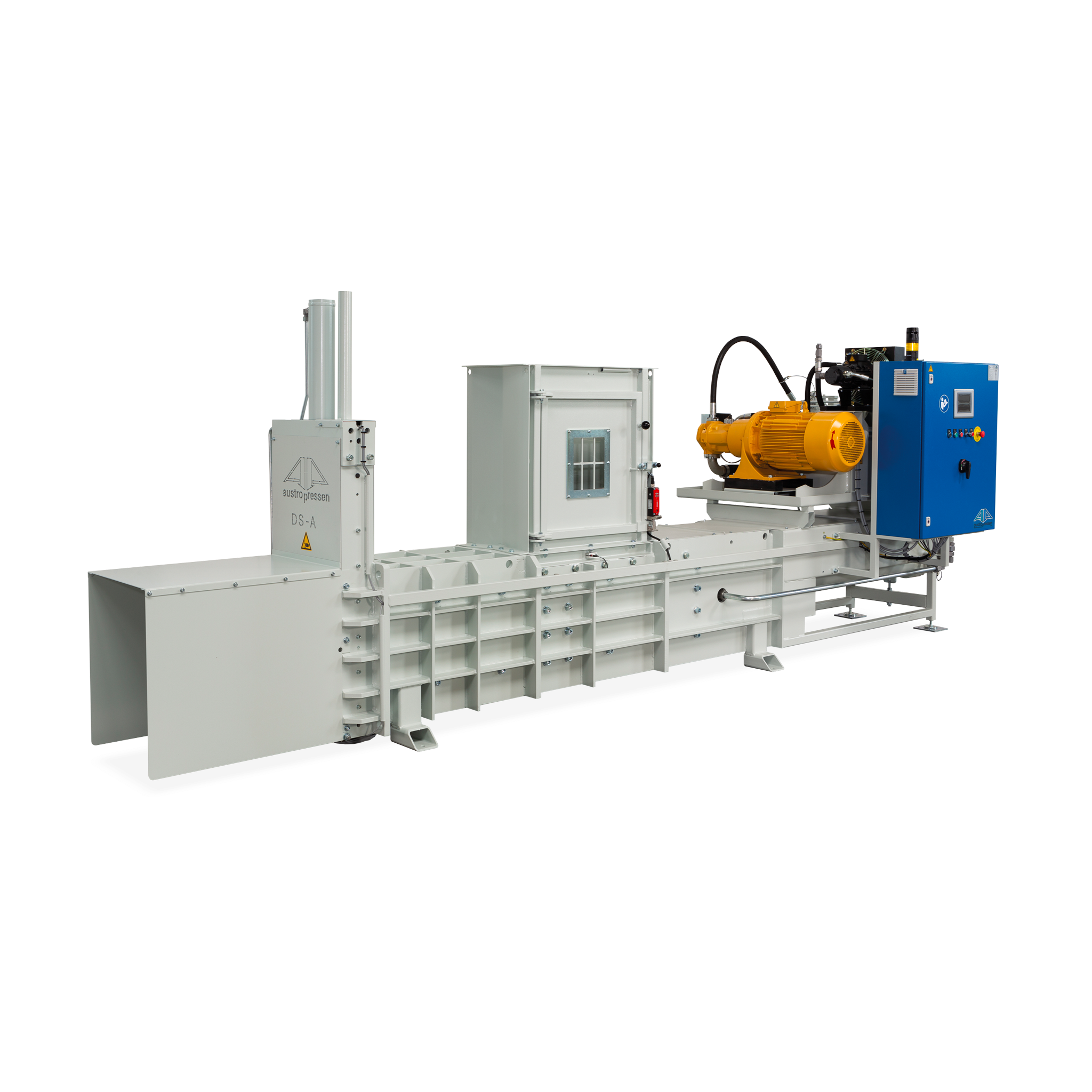

Automatic Aluminum Can Baler DS-A 680

The Fully automatic DS-A 680 can baler with cutting knives enables smooth continuous operation of aluminum and steel cans. It features special processed, replaceable wear plates made of HARDOX. The optimally designed press plate guidance in combination with two knives enable smooth continuous operation.

With aluminum cans a throughput of up to 700 kg/h achievable and 1900 kg/h with steel cans.

Easy and quick handling

Highly wear resistant and low-maintenance

Long lifespan and durability due to replaceable HARDOX wear plates

Encapsulated design provides maximum level of safety

Optional tipping device for additional logistics optimization

Categories

Automatic Scrap Metal BalersMaterials

MetalsNaN/undefined

Easy and fast handling

Wear resistant and nearly maintenance free due to changeable wear plates made of HARDOX

Optimally designed press-ram guide and cutting units guarantee a troublefree continuous operation

Optional tipping device for additional logistics optimization

Available with conveyor for a full automation of the feeding process

High durability and reliability based on our Austropressen quality standards

- ModelleDS-A 680/70-4545 | DS-A-680/80-4545 | DS-A-680/80-5045

- Press load680- 800 kN

- Specific press load400- 470 N/cm²

- Driver power22- 45 kW

- Theoretical throughput20- 28 m³/h

- Tinplated cans throughput1200- 2200 kg/h

- Filling hatch (LxB)800x400- 800x500 mm

- Bale format (LxB)450x400- 500x300* mm

- Bale length200 mm

- Dimensions (LxBxH)5200x1500x2200- 5400x1600x2200 mm

- Weight5500- 5800 kg

All models and full technical data:

With aluminum cans a throughput of up to 700 kg/h achievable and 1900 kg/h with steel cans.

Further products

Long-lasting quality from Austria

Years of designing and manufacturing high quality baling presses in Austria. This valid experience ensures reliability, durability and maximum efficiency of all Austropressen products.