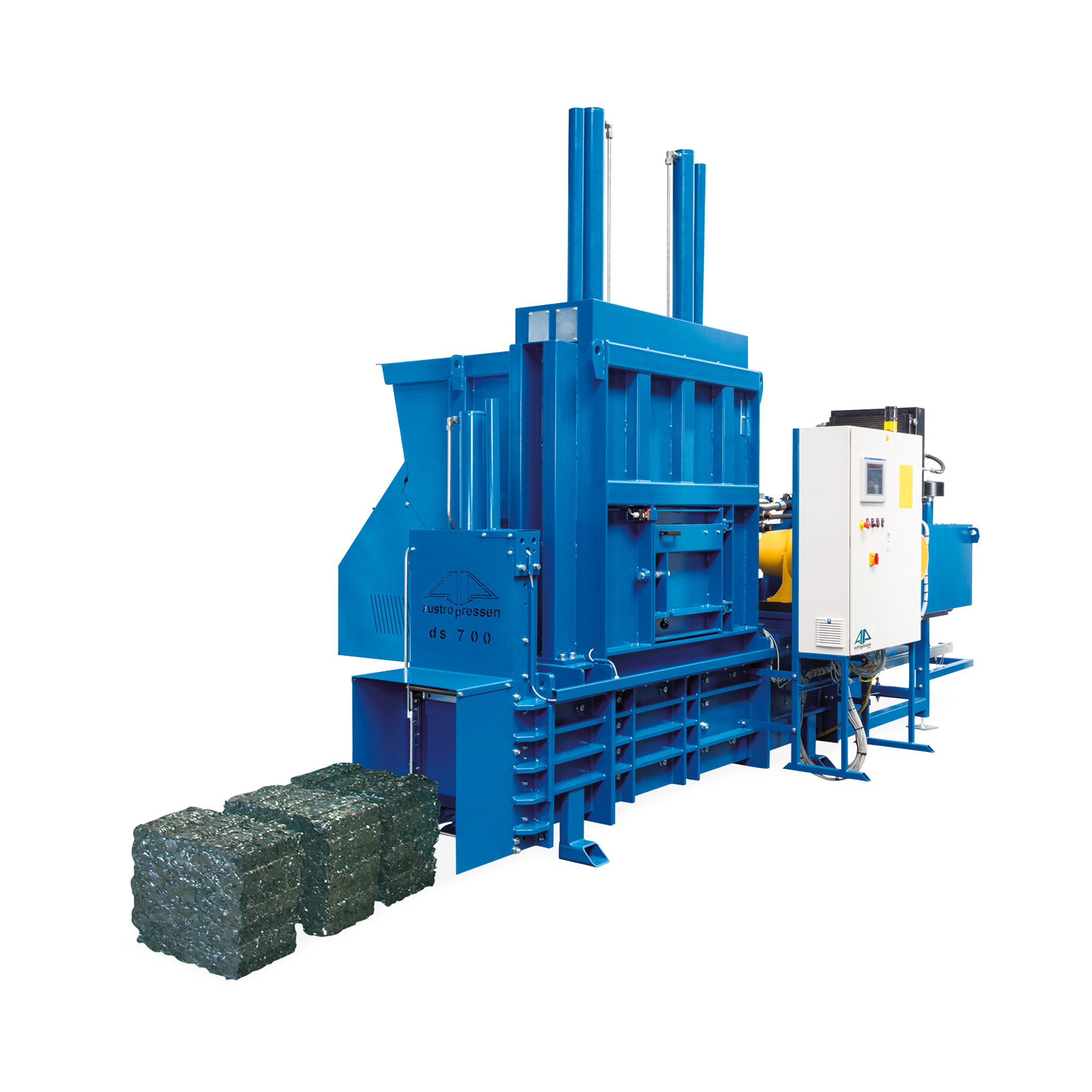

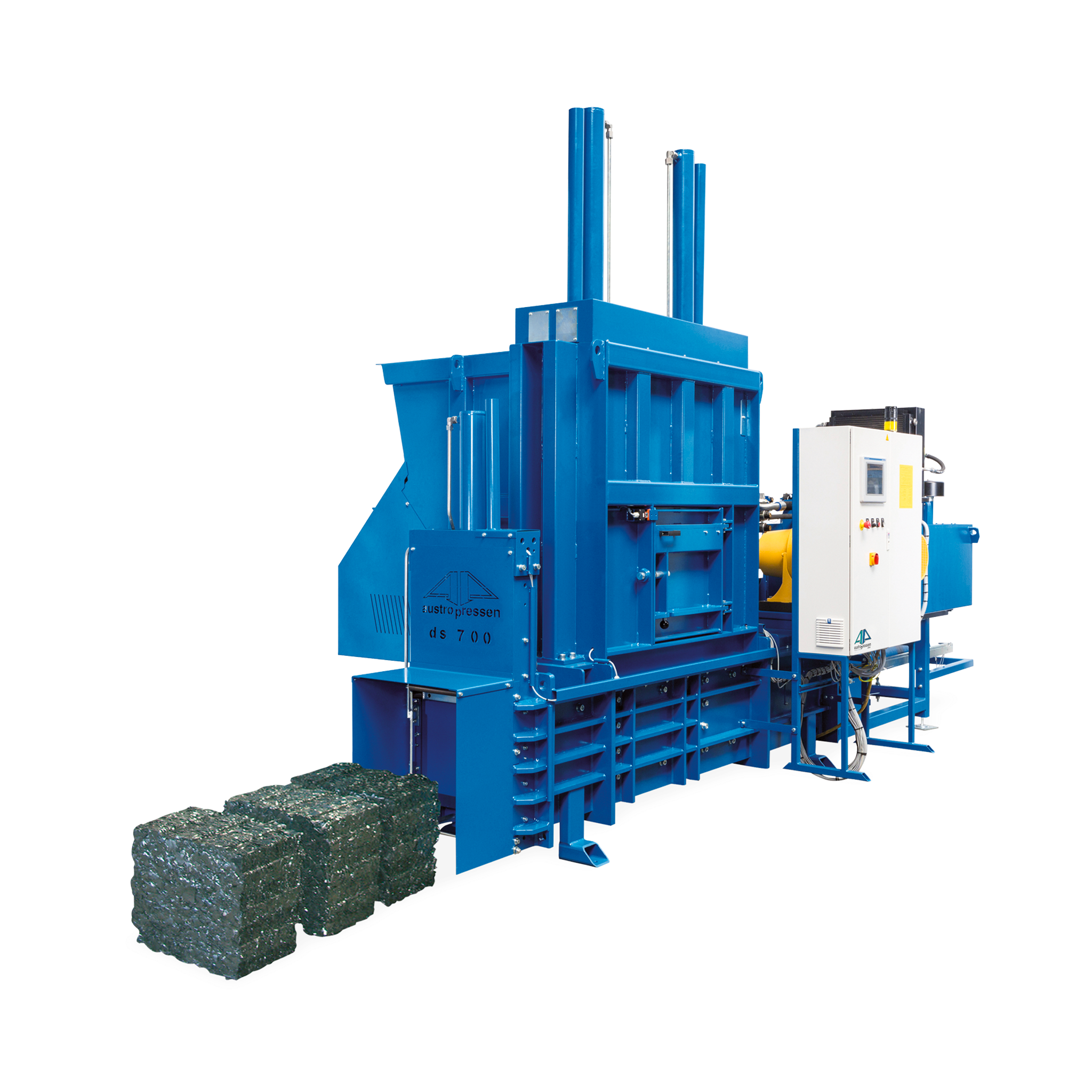

Automatic Can & Scrap Baler DS-A 700

Triple compaction in a single pressing cycle

Thanks to the sophisticated design of the press system, these automated can and scrap balers with their four cylinders ensure threefold compaction in just a single pressing cycle. This sensational innovation ensures massive compaction of the material to form bales that can be supplied directly to steel plants for recycling.

These can and scrap balers are the ideal solution for scraps from can production or from sorting plants. With aluminum scraps a throughput of 1600 kg/h and a density up to 600-700 kg/m³ is achievable. With tin plate a throughput of up to 2500 kg/h is achievable.

The main benefits:

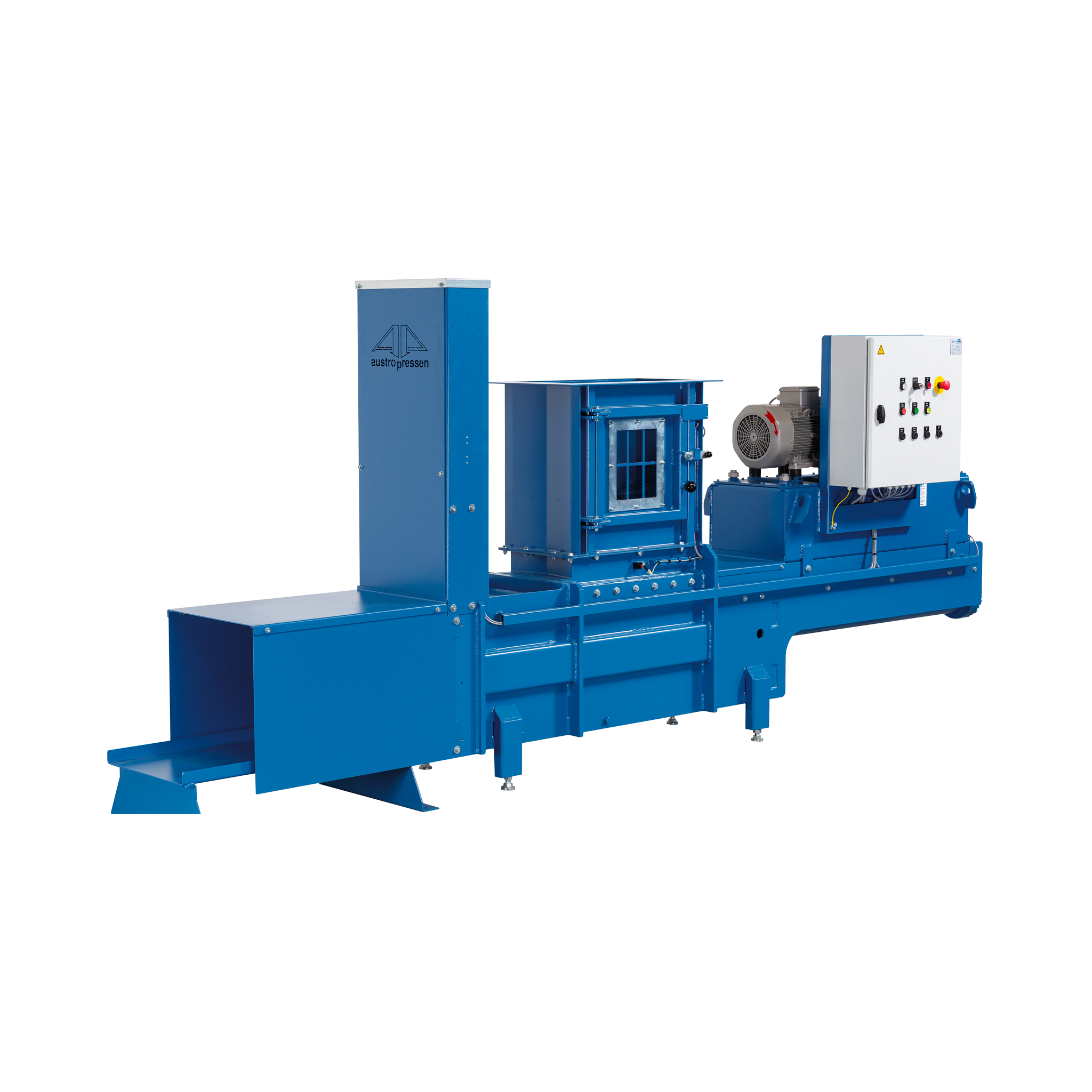

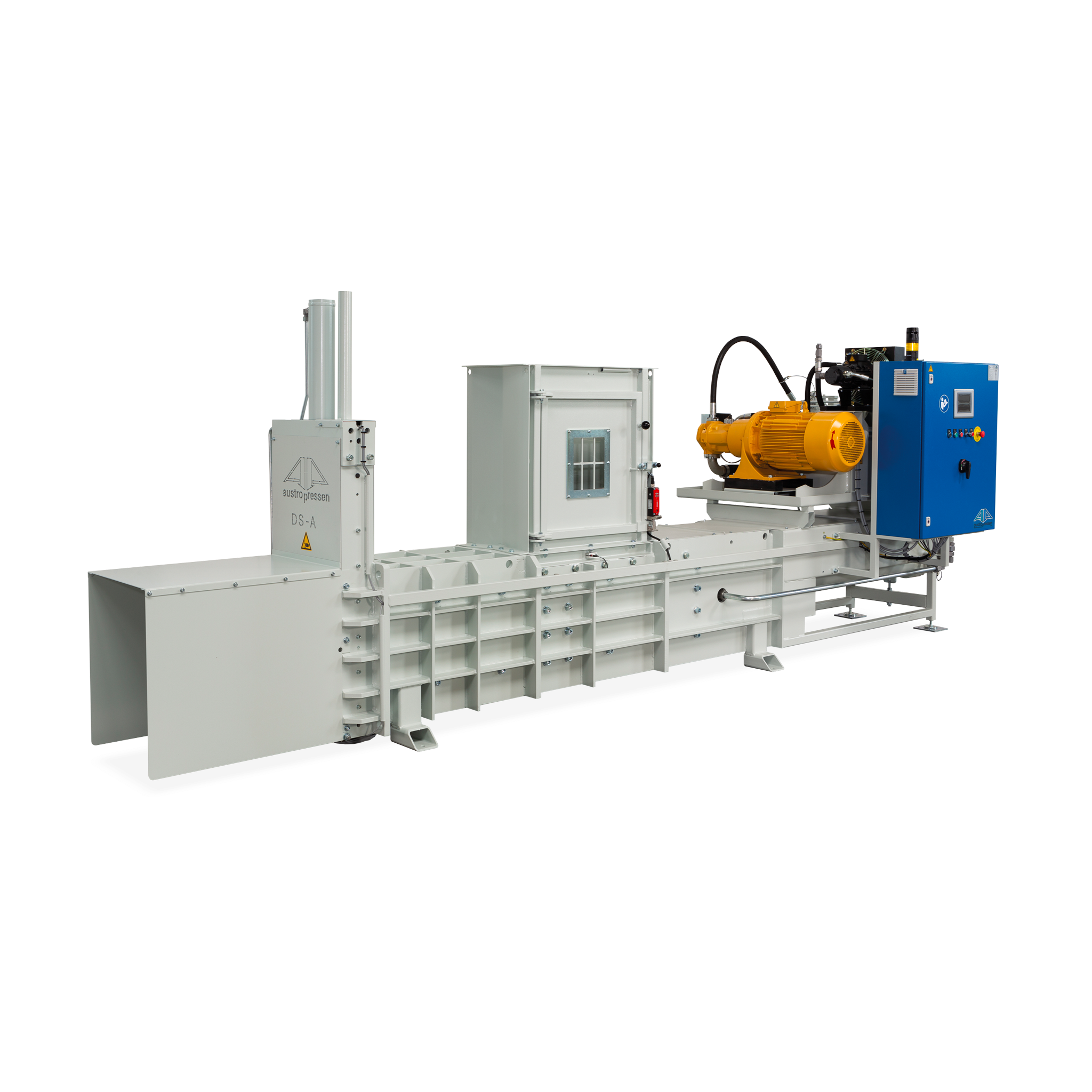

Fully automatic and continuous operation

Maximum ease of use and maximum operator safety

Highly wear resistant and low-maintenance

High density bales even with mixed material or little pre-sorting

Categories

Automatic Scrap Metal BalersMaterials

MetalsNaN/undefined

Fully automatic and continuous operation

Maximum ease of use and maximum operator safety

Highly wear resistant and low-maintenance

High durability due to replaceable HARDOX wear plates

High density bales even with mixed material or little pre-sorting

Performance monitoring via PLC; optionally expandable by data highway

Special control systems available on customer request

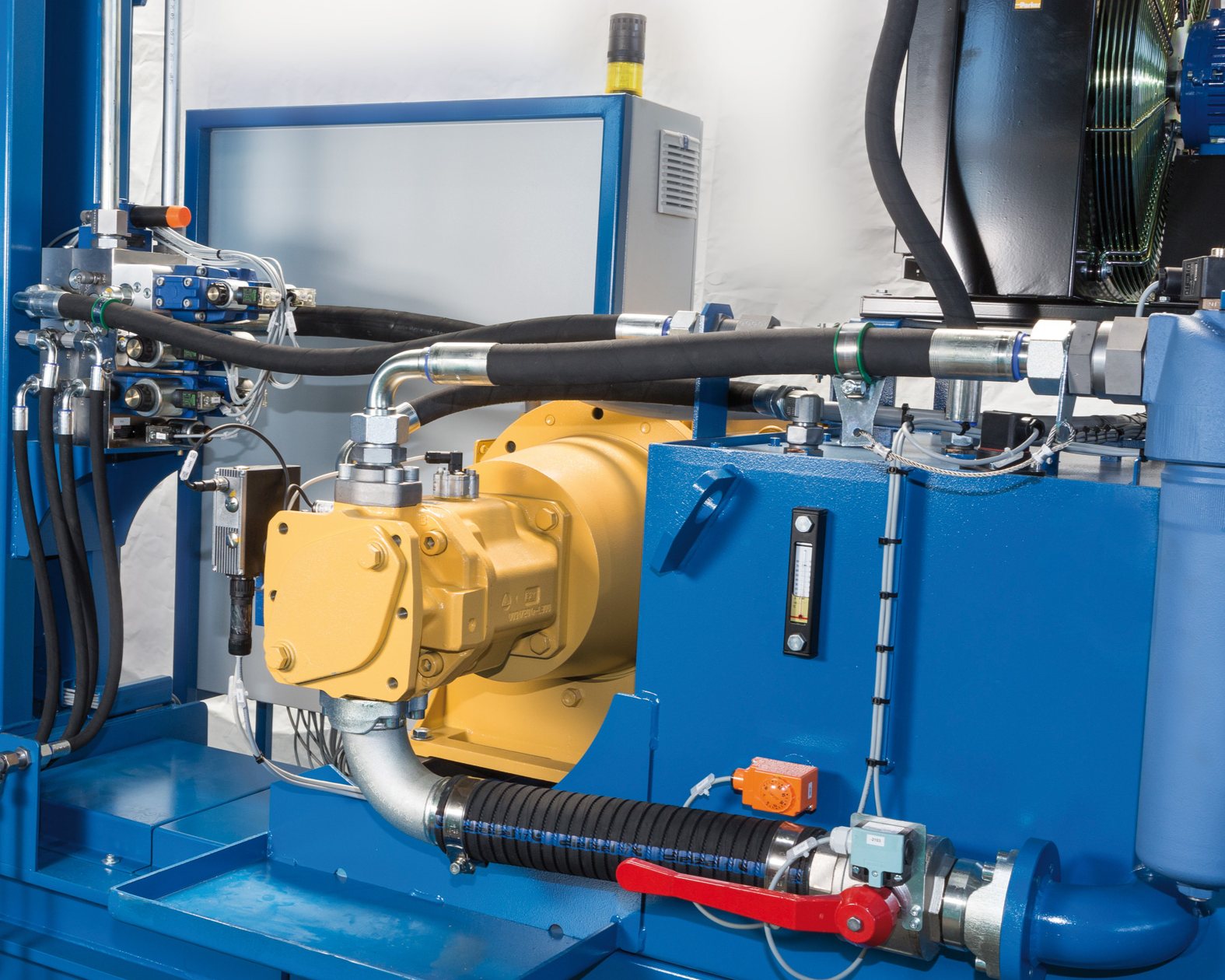

High energy efficiency due to use of innovative technologies

High durability and reliability based on our Austropressen quality standards

- ModelleDS-A 700/80-4545 | DS-A 700/85-4030

- Press load800- 1100 kN

- Specific press load509- 470 N/cm²

- Driver power30- 45 kW

- Theoretical throughput50- 70 m³/h

- Tinplated cans throughput3000- 4500 kg/h

- Filling hatch (LxB)1400x900 mm

- Bale format (LxB)450x350- 500x500 mm

- Bale length200- 200 mm

- Dimensions (LxBxH)5700x2400x3400- 6500x2450x3700 mm

- Weight8820- 9990 kg

All models and full technical data:

These can and scrap balers are the ideal solution for scraps from can production or from sorting plants. With aluminum scraps a throughput of 1600 kg/h and a density up to 600-700 kg/m³ is achievable. With tin plate a throughput of up to 2500 kg/h is achievable.

Further products

Long-lasting quality from Austria

Years of designing and manufacturing high quality baling presses in Austria. This valid experience ensures reliability, durability and maximum efficiency of all Austropressen products.