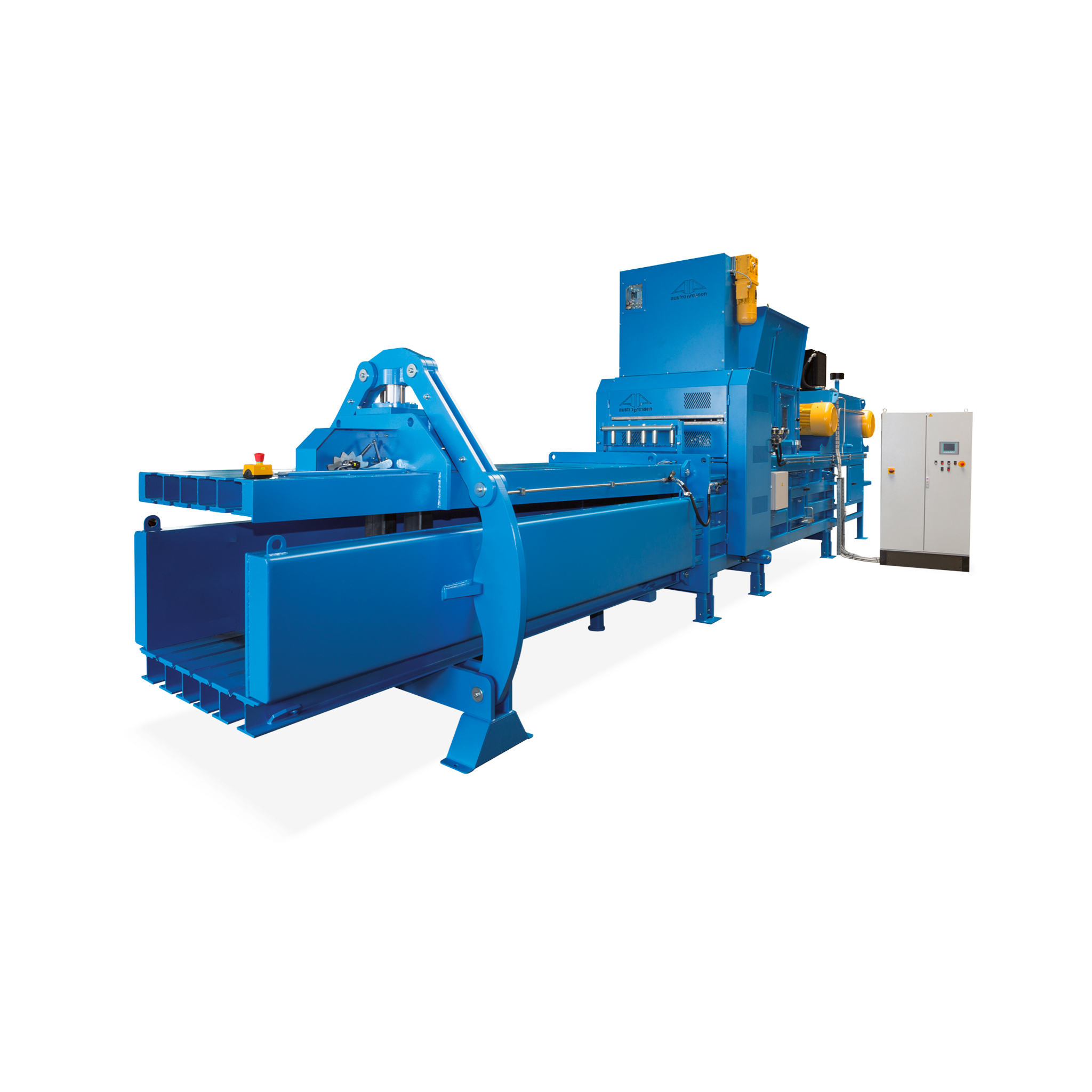

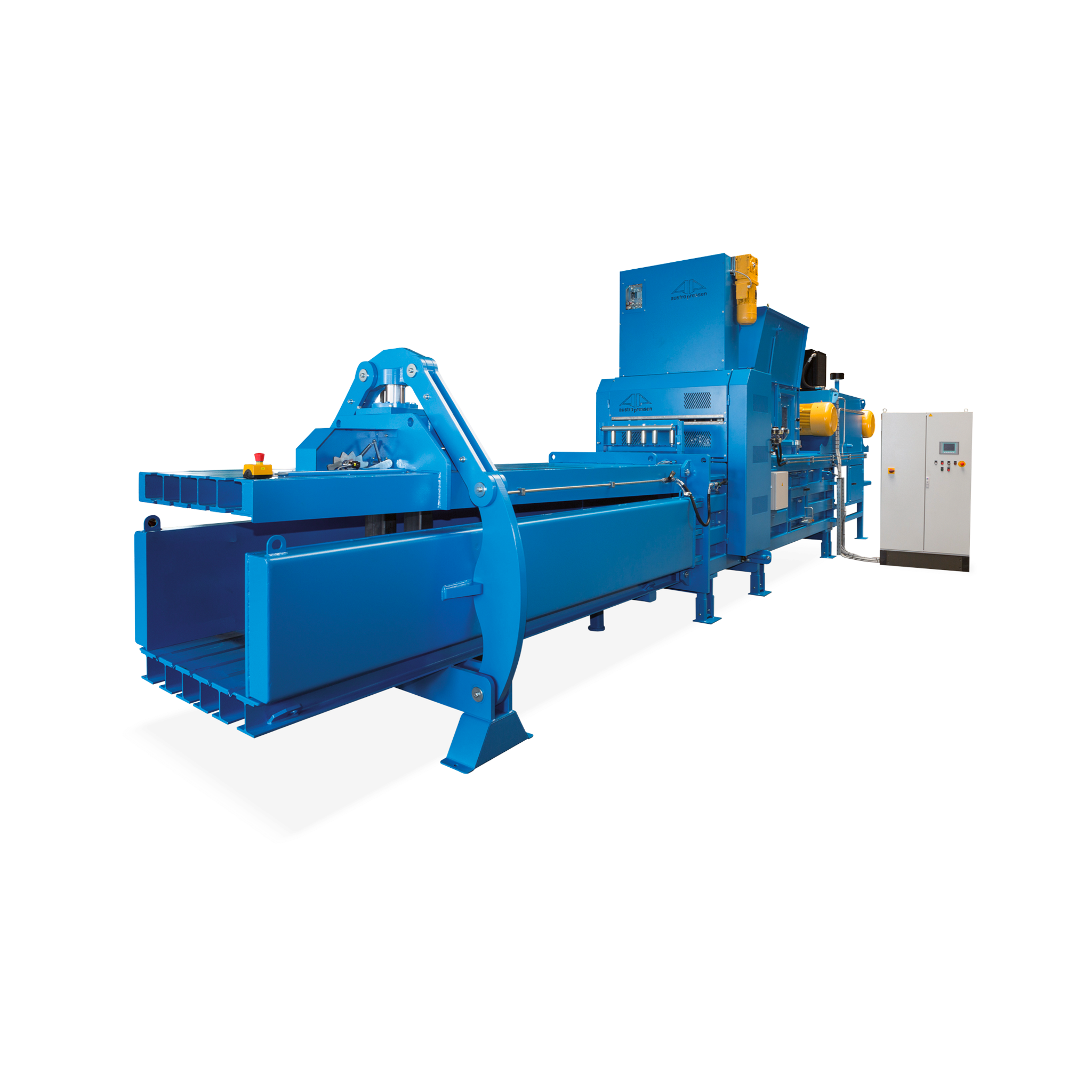

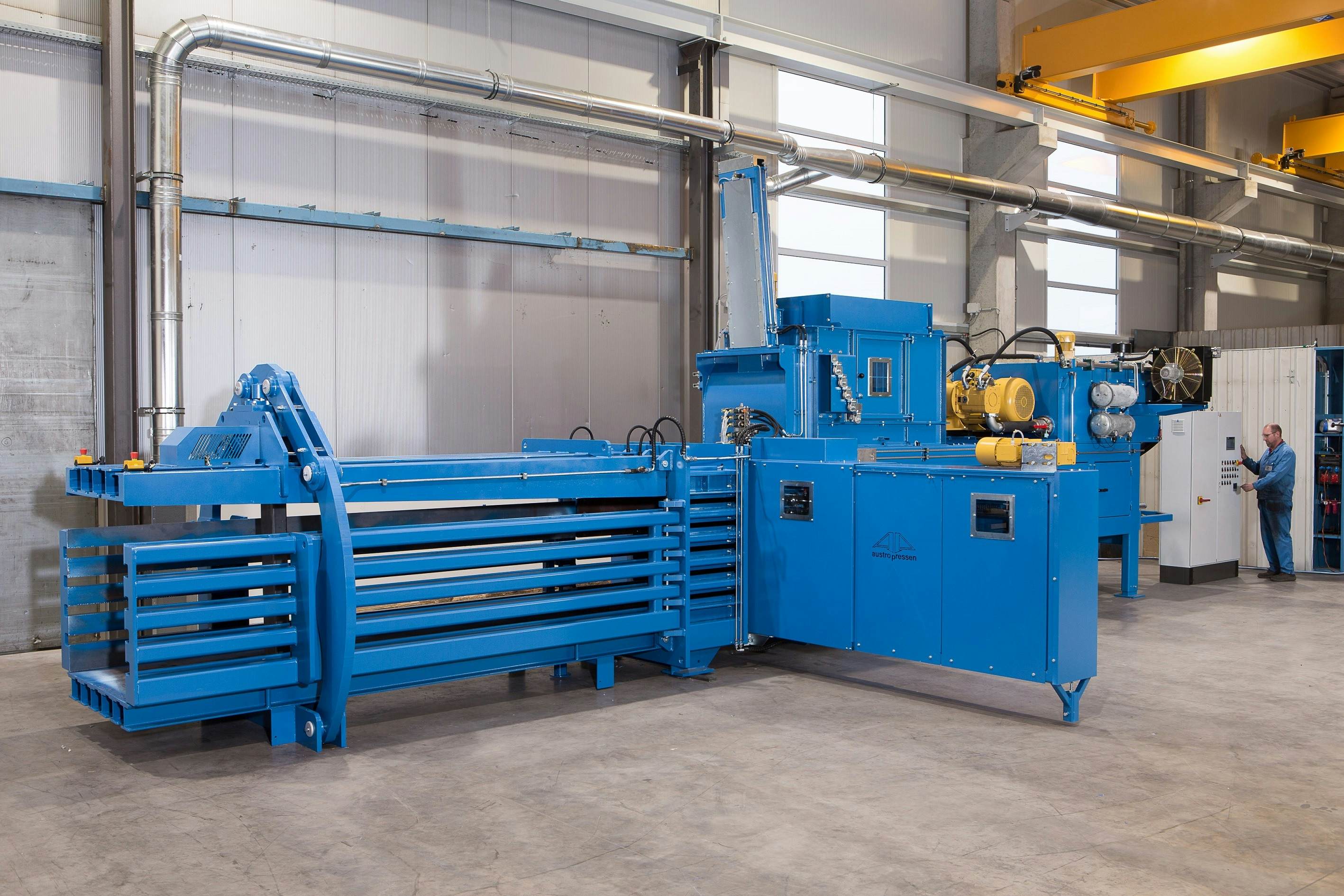

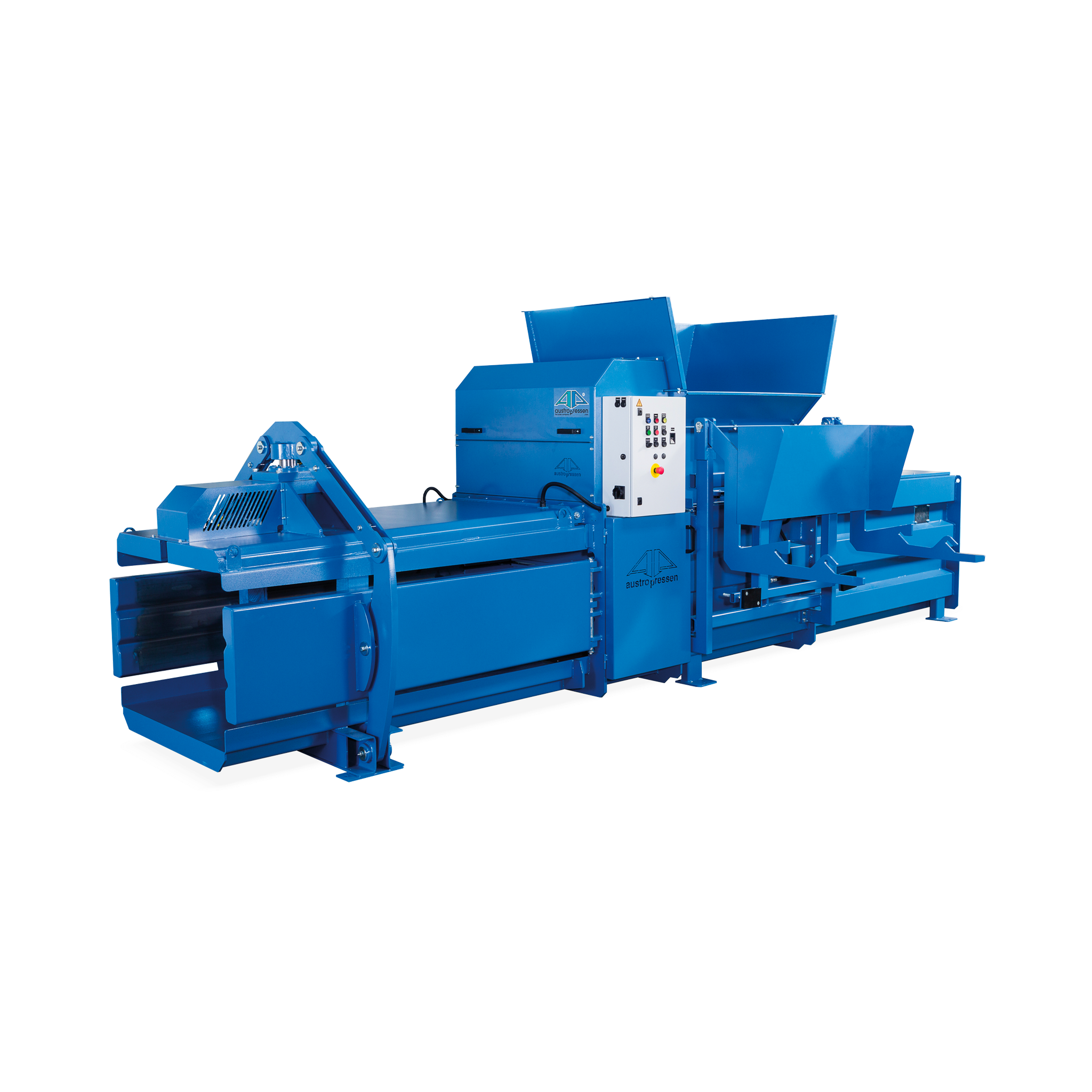

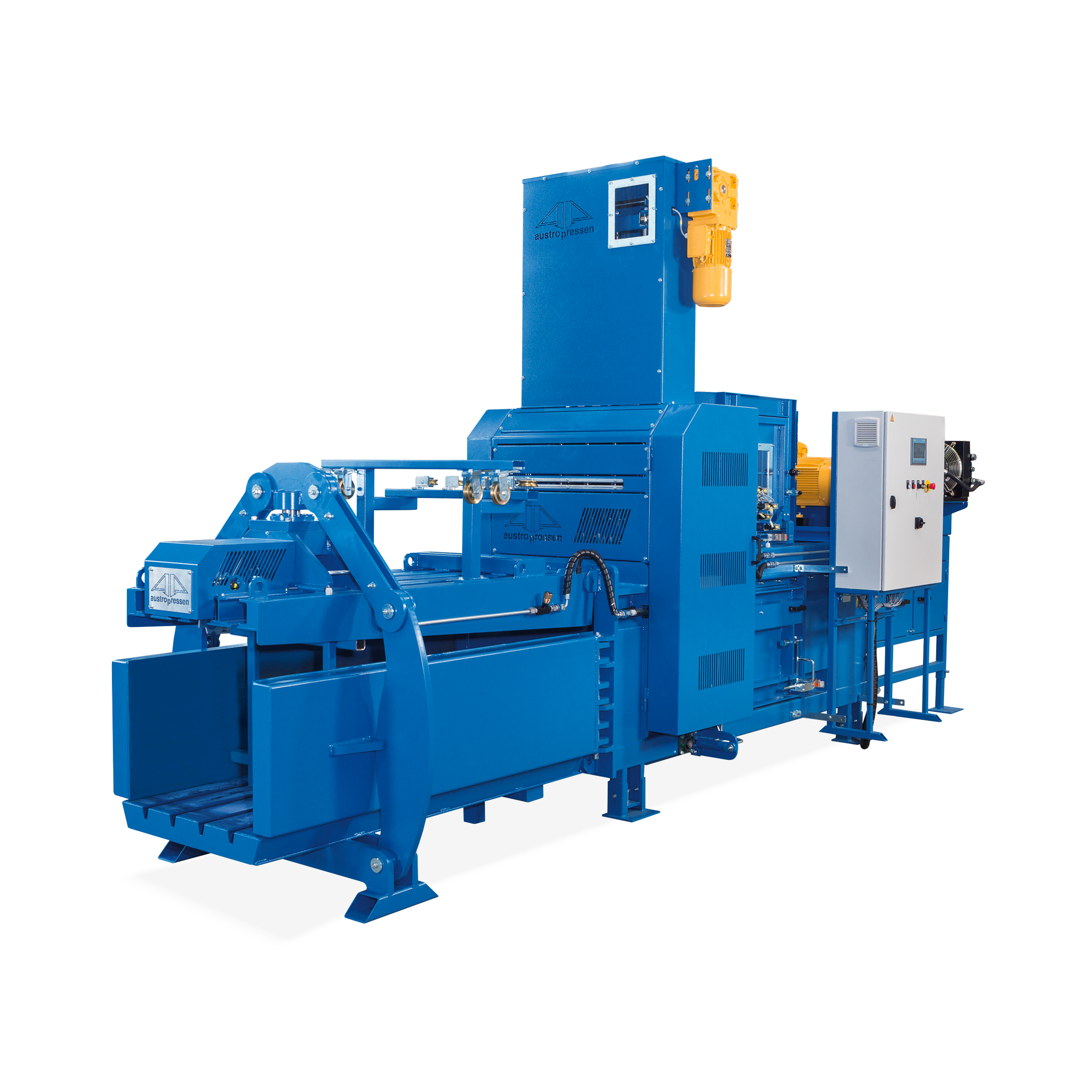

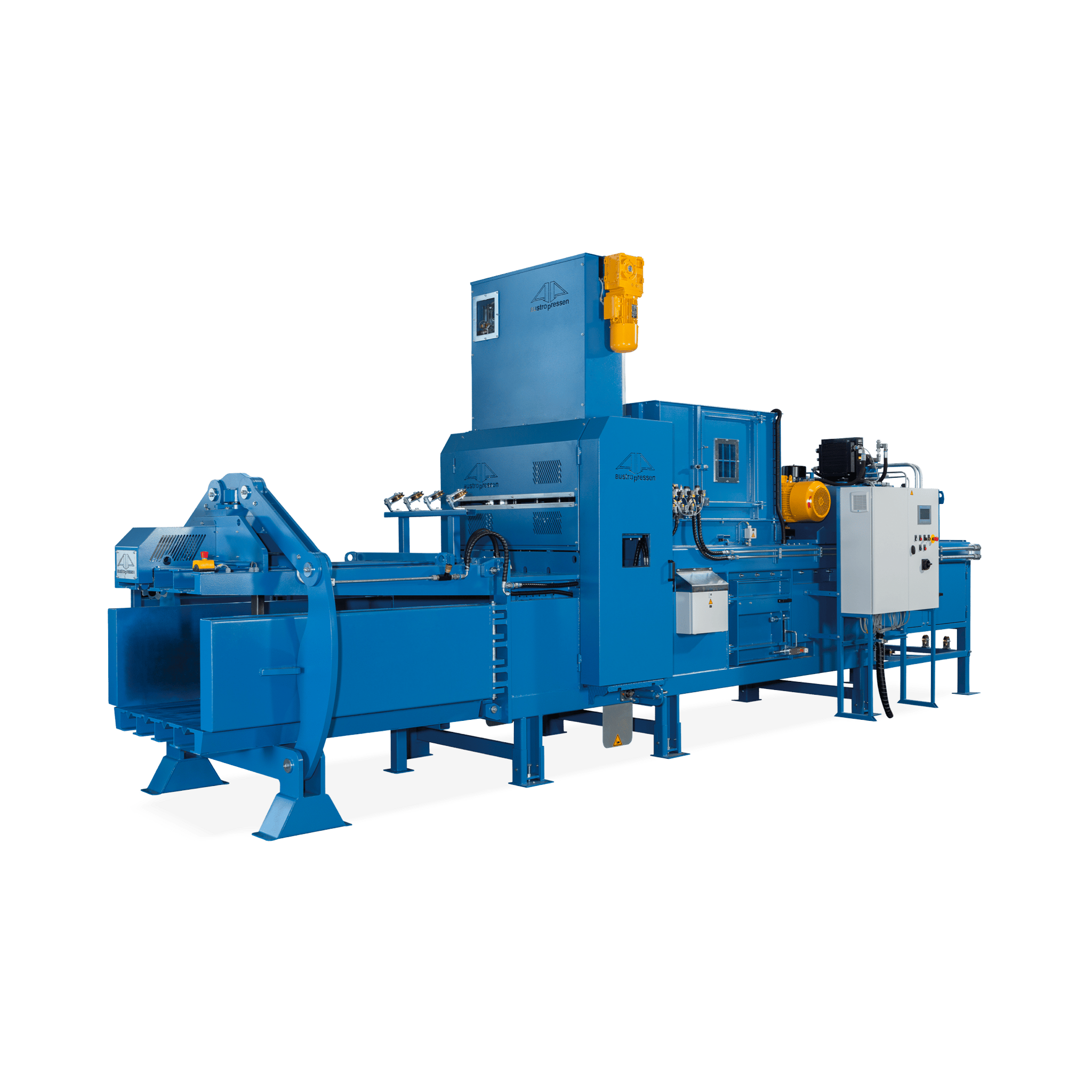

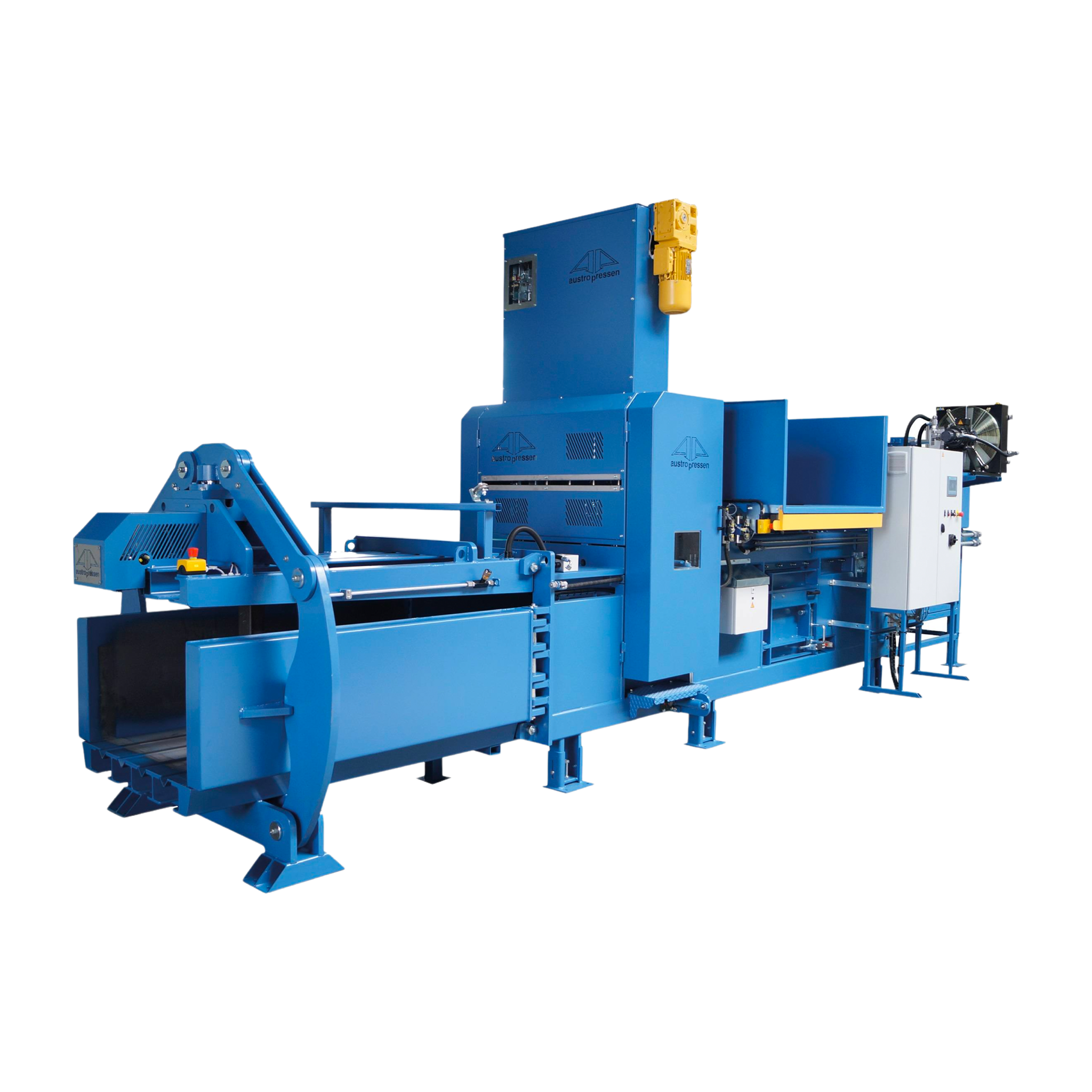

Automatic baler APK-ES 135 used by Energie AG ensures efficient waste management

Energie AG Umwelt Service offers sustainable waste disposal services throughout Austria. The processing of 1,000 tonnes of material per month at the Ötztal site is optimally fulfilled by the fully automatic Austropressen APK-ES135 channel baling press.