Nürnberg · DEFACHPACK 2025

Stand 7-725

Polyether foam PE, PU or PUR foam is used in countless applications: in car interiors and seats, as insulation or absorber in buildings, in medical technology for bandages and prostheses. Our customers include companies producing, using and recycling foam.

Close collaboration and constant dialogue with our customers results in technically advanced products that are ideally suited to the industry or application.

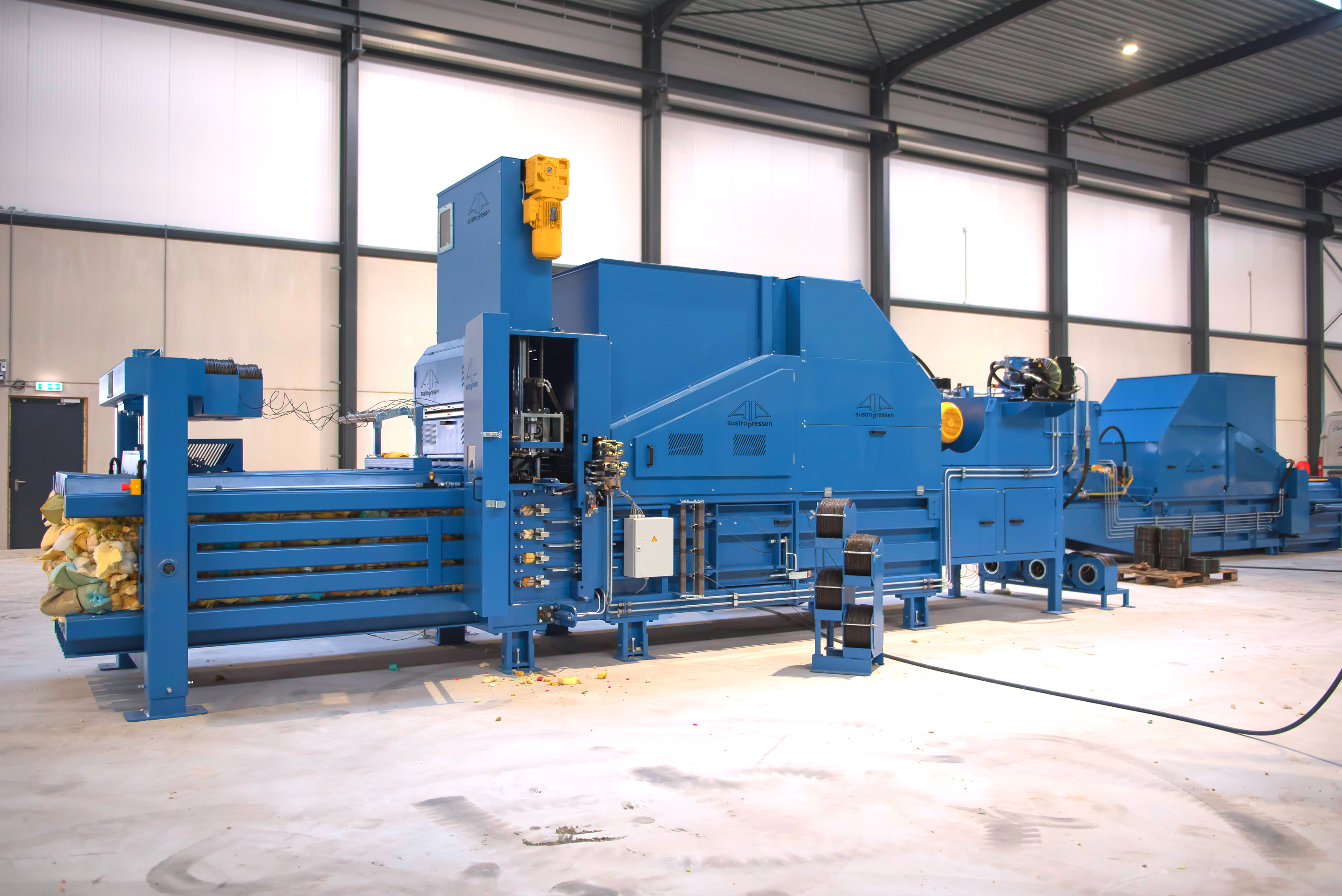

Impressive material testing, even with car tyres: with a bale size of 1000x700x1300mm and a bale weight of 660kg, the AP-42F can fit around 70 car tyres on a Euro pallet.

Customised, powerful and user-friendly. For the compaction of sponge, foam and other highly expandable materials, we offer two types of Austropressen foam balers: the powerful AP-42F with large feed opening and the fully automatic APK-F channel baler.

A huge reduction in waste volume can be achieved by compressing and bundling foam into bales. This offers great potential savings in storage, transport and disposal costs. Careful selection of the right machine is essential to ensure that bales of expansive materials retain their shape and do not become a safety hazard.

Our foam balers ensure maximum operator safety with features such as hydraulically controlled feed flaps and counter doors, constant monitoring of machine data via PLC and 8 to 9-fold wire cross-binding for dimensionally stable bales.

Dutch recycling company Retour Matras relies on the fully automatic APK-F60 from Austropressen to compact the collected mattresses. This powerful baling press, designed for foam and expanding material, meets all of the company's requirements.

Other balers in our range can also be used to compact foam, textiles and other expansive materials, depending on the quantity and characteristics of the material. We can help you choose the right baler for your application.

We get your waste in shape. The innovation, reliability and efficiency of Austropressen products have convinced even experienced users in all industries.

Years of designing and manufacturing high quality baling presses in Austria. This valid experience ensures reliability, durability and maximum efficiency of all Austropressen products.

Contact us and we will find the ideal solution for your company's use in a free consultation.